Completed funded project

Motivation

Ceramic components are subject to very high functional requirements in terms of temperature resistance, corrosion resistance and ductility, especially in applications in the aerospace industry and in safety and energy technology. In order to expand the possible applications of these materials, it is particularly important to optimise the impact and fracture sensitivity in all spatial dimensions through targeted fibre reinforcement. The low commercial availability of three-dimensionally reinforced structures motivates the development of carbon preforms which can be used in ceramic components.

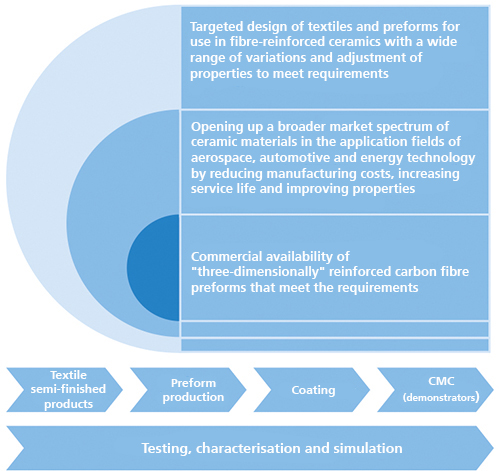

Objective

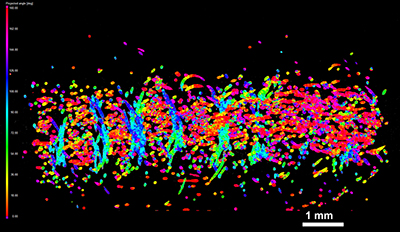

As part of the Federal Ministry of Education and Research's initiative "Technical textiles for innovative applications and products - NanoMatTextil", textile carbon fibre preforms with a defined Z-reinforcement were developed by needling and by tufting textile semi-finished products. These included highly drapable non-crimp fabrics and wovens as well as chopped carded nonwovens with defined fibre orientation. With a loading the fibre-matrix bond should be adjusted. By needling and tufting the semi-finished textile products, a defined Z-reinforcement should be achieved by reorienting the fibres so that, among other things, impregnation behaviour, ply adhesion etc. of nonwovens and sandwich composites can be specifically adjusted.

Results

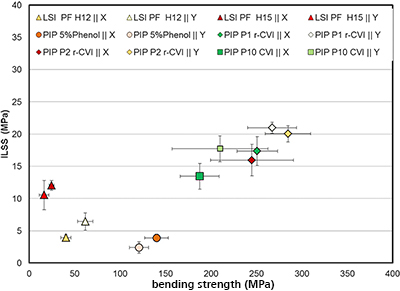

The results prove that high-strength fibre composites with up to 300 MPa can be produced on the basis of Z-reinforced textile preforms. At the same time, it was shown that Z-reinforced preforms are not equally suitable for all ceramisation processes and that they must therefore have a high degree of structural adaptability - such as handling capability, a specifically adjustable pore size distribution and fibre density as well as a fibre preference orientation - in order to produce high-performance composite ceramics.

Project Data

| Project Duration | 01.10.2014 - 30.09.2017 |

| Sponsor | Federal Ministry of Education and Research |

| Funding Amount | 2,360,000 Euro |

| Project Partners | Fraunhofer-Centre HTL Airbus SE University of Bayreuth University of Applied Sciences Hof Gustav Gerster GmbH & Co. KG Tenowo GmbH CVT GmbH & Co Schunk Kohlenstofftechnik GmbH ECM Engineered Ceramic Materials GmbH Research Society for Textile Technology Albstadt mbH Technical University Dresden - Insitute of Textile Machinery and High Performance Material Technology |

| Project Coordination | University of Applied Sciences Hof |

| Project Management at the HTL | Dr. Alexander Konschak |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth