Currently funded project

Motivation

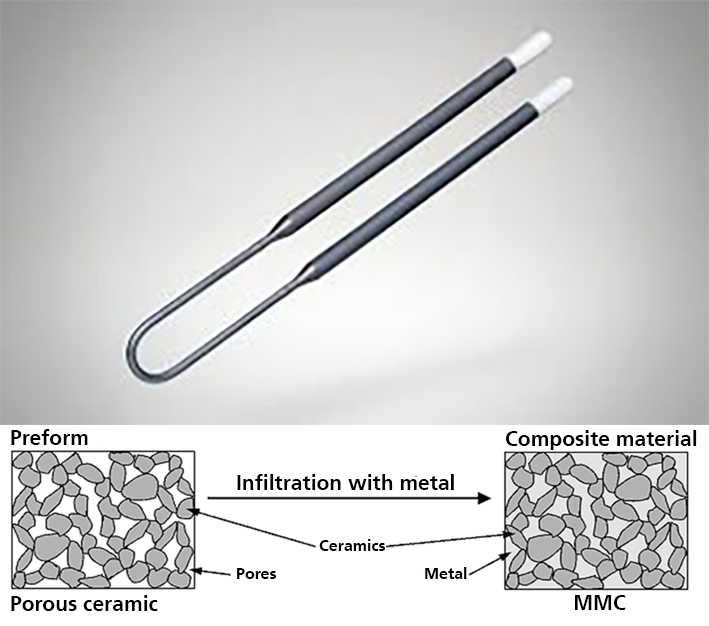

A large number of different heaters are available for industrial heating processes, but they can only be used in certain atmospheres, do not allow a change of energy source and sometimes have inadequate mechanical properties. Furthermore, in view of the long service life of industrial furnaces in the range of several decades, the energy source used plays an important role for cost efficiency and environmental friendliness. Heating by means of fuel gases is still much cheaper today than electrical heating, which will probably change in the next two decades with rising CO2 taxes and cheaper electricity from renewable energy sources. To enable flexibility in the use of the energy source and the combustion atmosphere, new types of heaters with improved thermomechanical properties are needed, which are currently not available.

Objectives

The objective of the joint project is to develop new types of MMC resistance heaters with the following property profile:

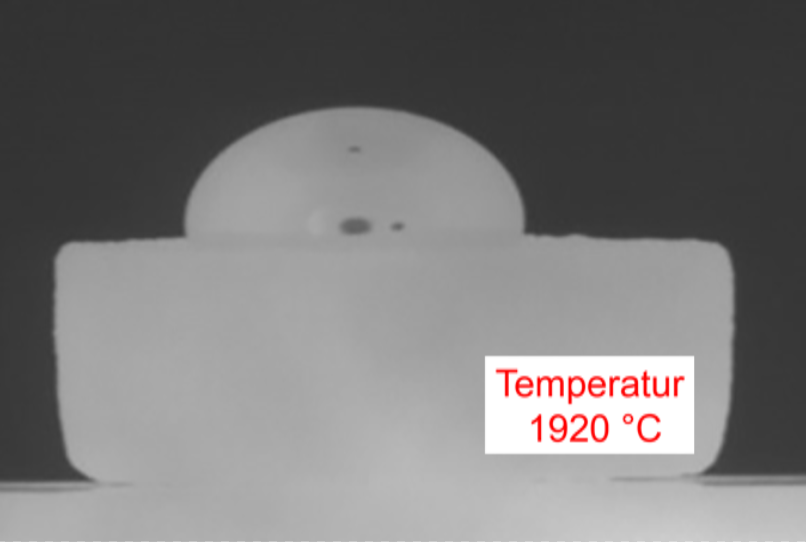

- Creep stability in the service temperature range 1600 °C - 1900 °C

- Degeneration-stable low-temperature strength > 200 MPa

- Versatile application atmospheres: Vacuum, oxidising, reducing and inert atmosphere

- Energy flexibility: gas or electricity as energy source

The newly developed heating elements are to be characterised and tested in the heating application with regard to their application behaviour.

Approach

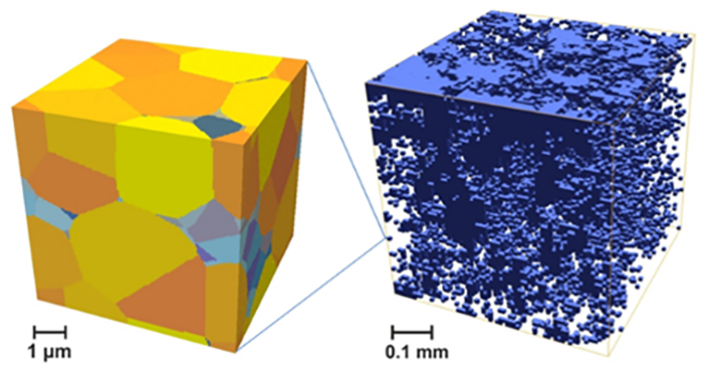

- Development of a novel composite material with electrically conductive component and creep-resistant support structure

- Gas-tight coating of the composite material as corrosion protection

- FE-based design of conventional heaters (electrically heated) and radiant tube heaters (electrically or gas heated)

- Development and production of prototype heaters with protective coating

- Characterisation of the prototypes in the heating application

- Design of a hybrid furnace, construction of a furnace demonstrator using the developed heating elements

Project Data

| Project Duration |

01.05.2021 - 30.04.2024 |

| Sponsor |

Bavarian State Ministry for Economic Affairs, Regional Development and Energy |

| Funding Amount HTL |

330.000 Euro |

Project Partners |

Fraunhofer-Center HTL Paul Rauschert Steinbach GmbH Konrad Schmidling GmbH Erich Netzsch GmbH & Co. Holding KG |

| Project Coordination |

Paul Rauschert Steinbach GmbH |

| Project Management at the HTL |

Christian Eckardt |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth