Currently funded project

Motivation

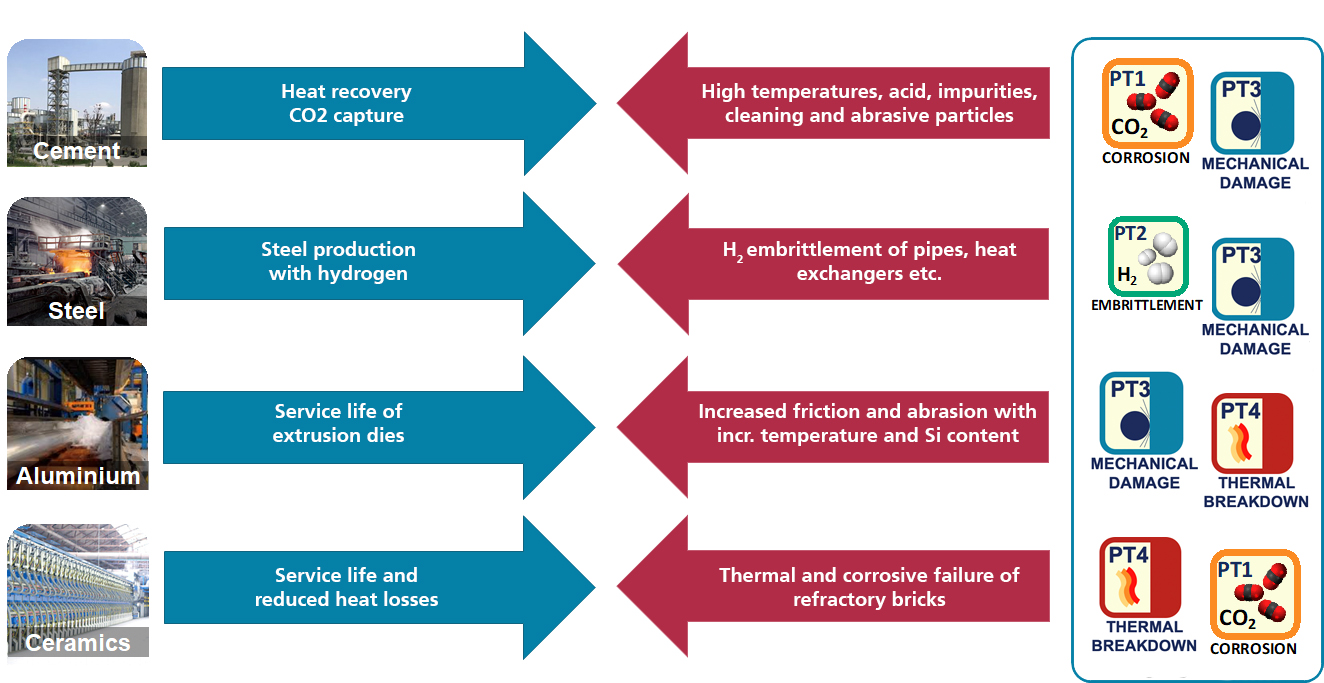

The EU Horizon 2020 funding programme aims to support the transformation process of energy-intensive manufacturing industries towards carbon neutrality in 2050. In the joint project FORGE, four key challenges (H2 embrittlement, corrosion, abrasion, and mechanical and thermal damage) and four key technologies (cement, steel, aluminium and ceramics production) are addressed.

Objectives

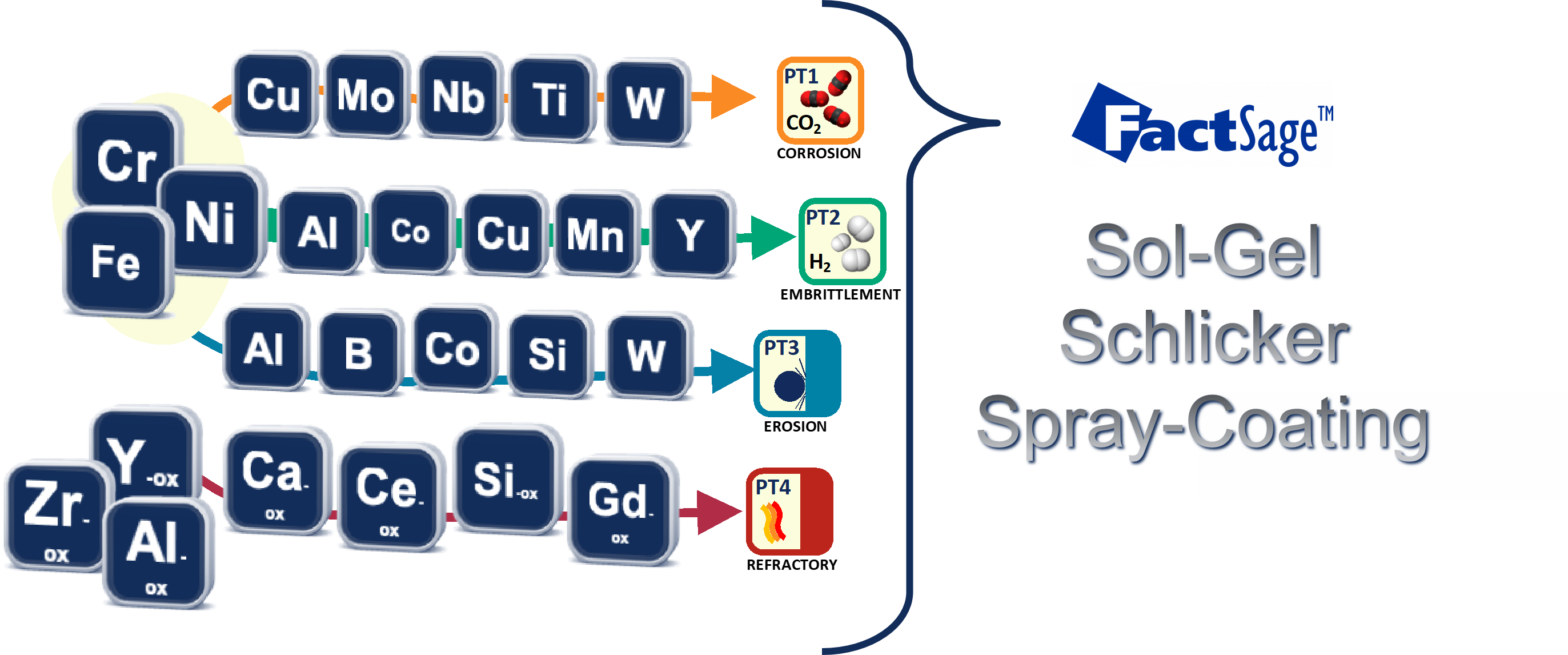

The project objective at HTL is the development of novel coatings to reduce the thermal and corrosive degradation of the refractory material in a tunnel kiln. The focus is on metallic and ceramic coatings with complex entropy-stabilised compositions, so-called Compositionally Complex Alloys CCA or Ceramics CCC. The compositions will be developed by a combination of AI and ML methods, computational chemistry, thermodynamic considerations and high-throughput experiments. For in-situ sensing, luminescent elements will be added.

Approach

- Pre-selection of suitable oxides for CCC based on experience and literature research

- Preparation of systematically varied compositions via sol-gel route, drying, pulverisation and sintering

- FactSage calculations for phase stability

- Evaluation of coatings by means of μ-CT, XRD, density and optical appearance as well as calculated thermo-physical properties using AI and ML methods

- Selection of potential compositions for corrosion experiments

- Transfer of the sol-gel process to slip-based processes

- Spray coating of refractory material

- Application of the coating in the furnace

You can find more information about the project here.

Project Data

| Project Duration | 01.11.2020 - 31.04.2024 |

| Sponsor |

European Union’s Horizon 2020 research and innovation programme |

| Funding Amount | 480,000 Euro |

Project Partners

|

Fraunhofer-Center HTL MBN Nanomaterialia S.p.A. Çimsa Çimento Sanayi ve Tic. A.Ş TWI Ltd Tailorlux GmbH EMPA ASAŞ Alüminyum Sanayi ve Tic. A.Ş Max-Plank-Institut für Eisenforschung GmbH ITC-AICE OnderzoeksCentrum voor de Aanwendig van Staal AeonX AI SAS Technovative Solutions Ltd University of Leicester |

| Project Coordination | MBN Nanomaterialia S.p.A |

| Project Management at the HTL | Dr. Holger Friedrich |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth