Currently funded project

Motivation

Europe has the goal of becoming a climate-neutral continent by 2050. To achieve this goal, renewable energies must be researched and energy-efficient processes and clean low-CO2 technologies must be provided. However, the use of renewable energies leads to fluctuating process conditions. Energy-intensive industries therefore need new materials that can be used under these changing process conditions, such as very high temperatures or corrosion. Ceramic Matrix Composites (CMC) represent a group of materials that can withstand these extreme requirements.

Objective

The aim of CEM-WAVE is to develop an innovative CMC production process based on a microwave-assisted CVI process. This new process should lead to improved properties of CMC as well as drastically reduce manufacturing costs and thus open up an application in energy-intensive sectors such as the steel industry. In the project, new types of CMC tubes are to be produced, equipped with sensors and validated in a jet tube furnace. The aim of the CMC material development is to produce composites with a weak interface (WIC = Weak Interface Composites) as well as CMC with a weak matrix (WMC = Weak Matrix Composites).

Approach

At the HTL, ceramic fibre preforms will be produced for the project partners. This work includes:

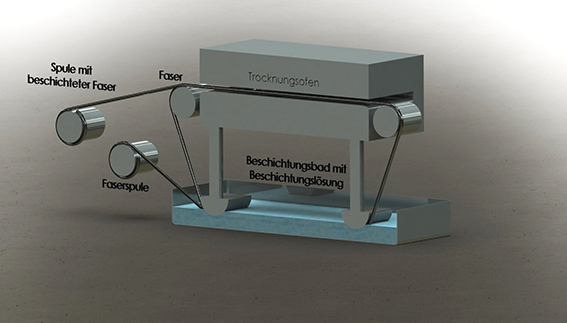

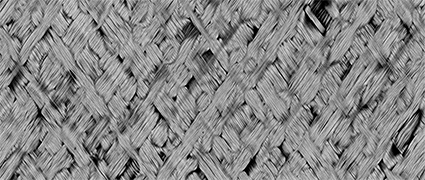

- Wet chemical fibre coating of SiC fibres (ZMI, SA3, Hi-NicS) and oxide fibres (N610 & N720) in a continuous roll-to-roll process

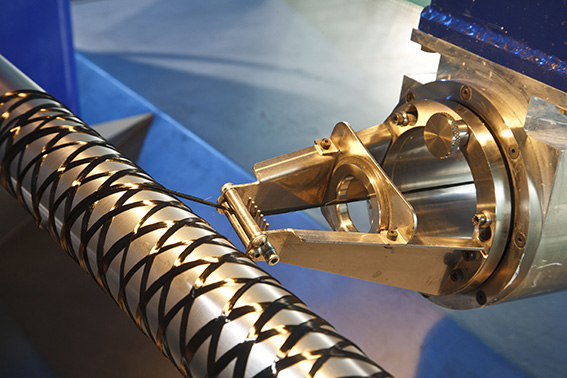

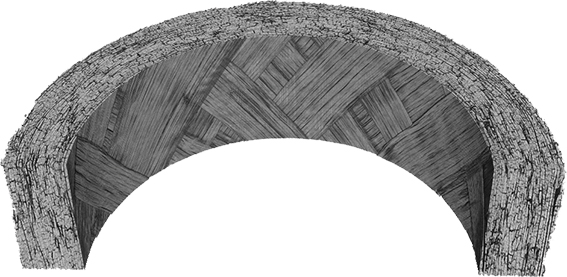

- 3D preform manufacturing by wet winding and prepreg technology with coated and uncoated ceramic fibres

- Characterisation and quality testing of porous fibre preforms using computer tomography

- Production of suitable fibre preforms for CVI microwave infiltration, joining tests and characterisation

Click here for the project website CEM-WAVE.

Project Data

| Project Duration |

01.10.2020 - 31.03.2024 |

| Sponsor | European Union’s Horizon 2020 research and innovation programme |

| Funding Amount | 464,000 Euro |

| Project Partners | Fraunhofer-Zentrum HTL Università di Pisa (UNIPI) Istituto per i Processi Chimico Fisici (IPCF-CNR) Fricke und Mallah Microwave Technology GmbH (FM) University of Birmingham (UOB) Advanced Coating Solutions Ltd (ATL) Agenzia nazionale per le nuove tecnologie, l'energie e lo sviluppo economico sostenibile (ENEA) Centre national de la recherche scientifique (CNRS) Steinbeis Advanced Risk Technologies Group GmbH (R-Tech) Politecnico di Torino (Polito) ArcelorMittal S.A. (AMIII) IRIS Technology Group SL. Kneia SL. |

| Project Coordination | Prof. Andrea Lazzeri, Universität Pisa |

| Project Management at the HTL | Dr. Alexander Konschak |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth