Completed funded project

Motivation

The service life of well-designed thermal processing plants is more than 30 years, although the refractory materials used have to be replaced more frequently, thereby reducing the carbon footprint and cost efficiency. If the refractory materials fail prematurely, major damage can occur. Precise requirements for the furnace materials based on furnace models and knowledge of the thermomechanical properties and failure behavior of the materials make it possible to avoid accidents and extend maintenance cycles.

Objective

In this sub-project, methods were to be developed with which the probability of failure of refractory materials can be predicted on the basis of their microstructure. Strategies for improving future refractory materials were to be derived from this. In addition, experimental methods were to be developed with which the ageing of refractory materials can be investigated under controlled conditions. Finally, measurement methods were to be developed in the process for recording high-temperature material data, as required as input for the simulation models in subprojects 1 and 3.

Results

- Basic microstructural, mechanical and thermomechanical characterization of selected refractory materials for the combination of mechanical and imaging non-destructive testing (presentation of the failure models in sub-project 8)

- Regular operation of TOM_wave at room and high temperature for:

- Laser flash tests for measuring thermal diffusivity and emissivity

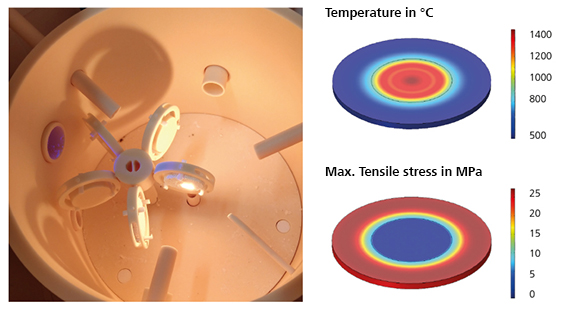

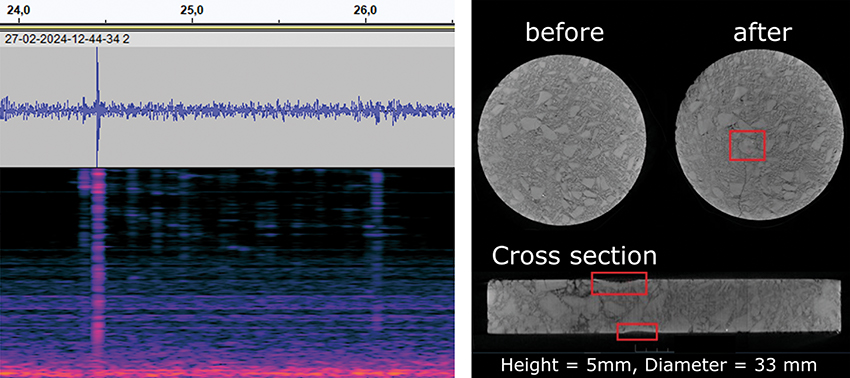

- Thermal shock and thermocycling tests for ageing under defined conditions

- Detection of acoustic emissions in refractory material during crack formation due to laser-induced thermal stresses

- Development of measurement methods for optimizing the debinding of samples containing high binder content for sub-project 3

- Development of measurement methods for the investigation of thermal processes with hydrogen

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth