Currently Funded Project

Motivation

Oxide fibre reinforced ceramics (O-CMC) are strategic materials for the European manufacturing, energy and aerospace industries. They are used in next-generation aircraft engines, stationary gas turbines, power-to-X processes with concentrated solar power CSP, in the chemical industry or even as charge carriers for high-temperature processes. Currently, such high-end O-CMC components and their individual components - the ceramic fibres as reinforcing components - are the key to this class of materials. Oxide ceramic reinforcement fibres have so far been produced mainly in the USA. The aim is for the European O-CMC component industry to become independent of fibre manufacturers from non-EU countries.

Objectives

- Development of a European oxide ceramic reinforcement fibre equivalent to state-of-the-art fibres from USA / Japan to be available to end users without dual-use restrictions.

- Development and validation of a next generation fibre with improved thermo-mechanical properties (Next Generation Oxide Fibre / NGO fibre) compared to state-of-the-art fibres to make processes, equipment, turbines, etc. more energy efficient through higher application temperatures.

Approach

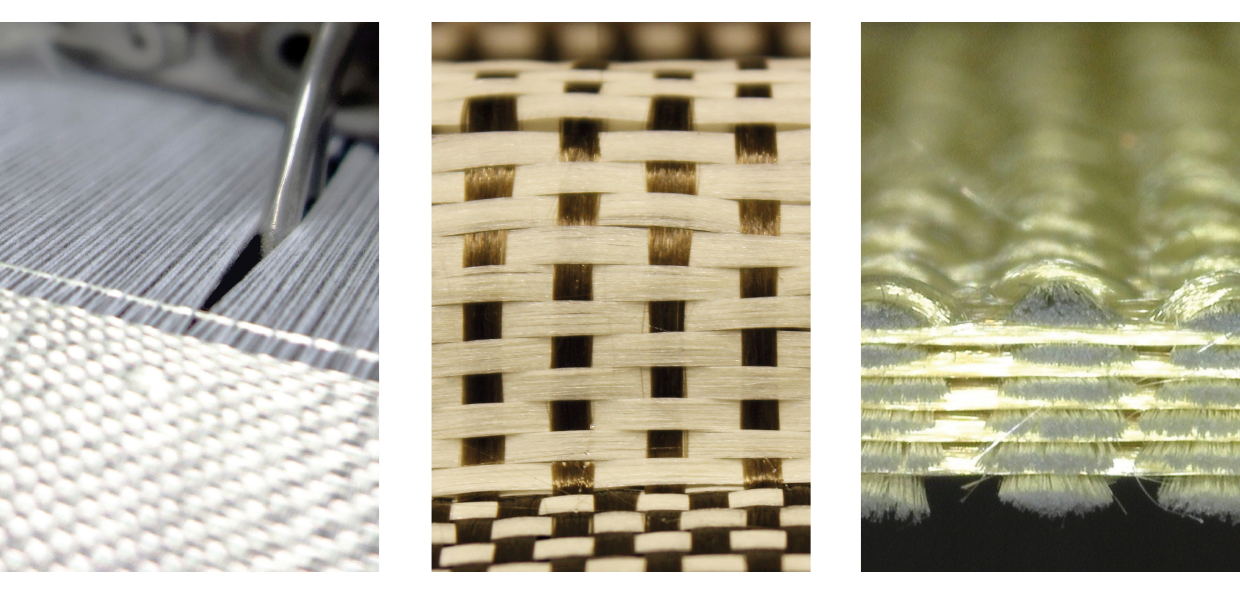

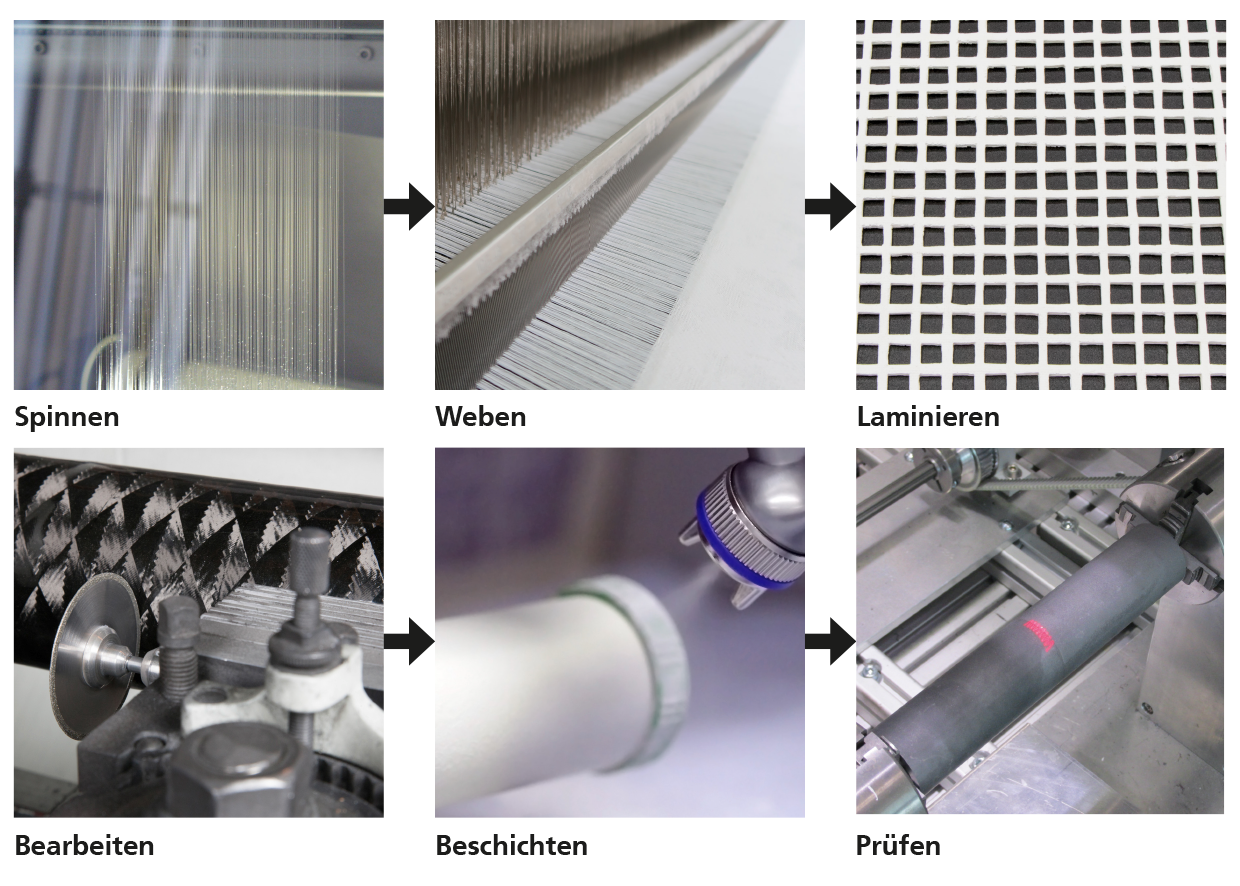

The project covers the entire process chain, from fibre development, weaving, O-CMC production, coupons and demonstrators for each end-user application, to testing Ox fibres and O-CMC components in relevant environments.

Project Data

| Project Duration | 01.05.2022 - 31.04.2025 |

| Sponsor |

European Union’s Horizon Europe Research and Innovation Programme |

| Funding Amount |

2.28 Million Euros |

Project Partners

|

Fraunhofer Center HTL Amires ArianeGroup Centre national de la recherche scientifique cnrs Netherlands Aerospace Centre NLR Porcher Industries SA Pyromeral Systems Rath Gruppe Paul Rauschert GmbH & Co. KG Safran S.A. University of Limoges |

| Project Coordination | Fraunhofer Center HTL |

| Project Management at the HTL | Ralf Herborn |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth