Currently funded project

Motivation

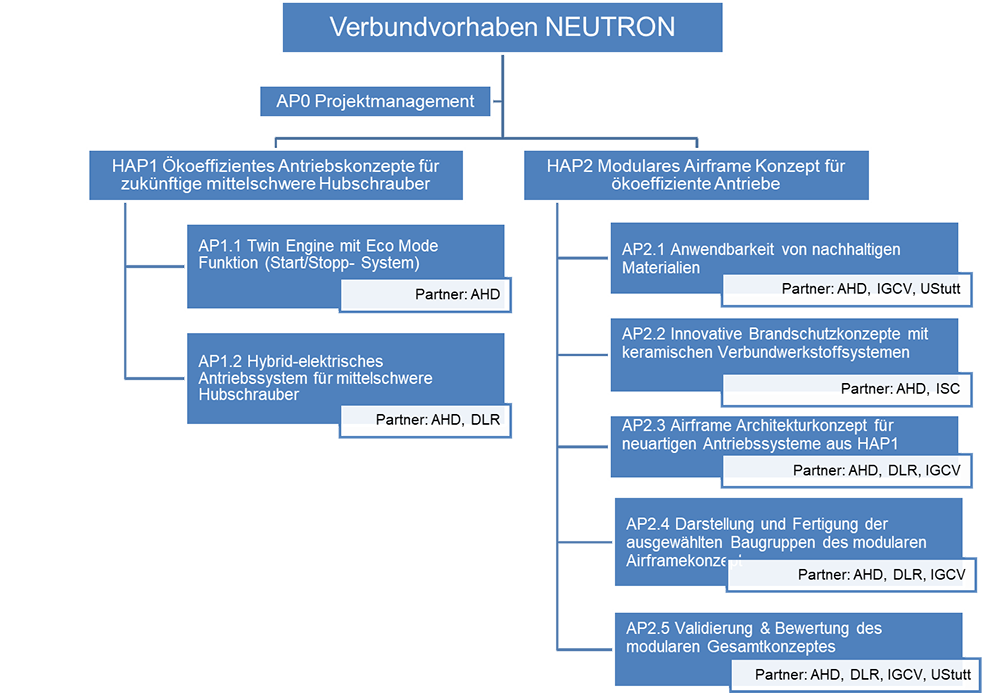

The use of electrified propulsion systems increases the acceptance of aviation in society due to their "green" and innovative character. In addition, there is the positive aspect of noise reduction. In the partner project "NEUTRON - ELECTRON", novel lightweight construction methods and production technologies for use in medium-weight helicopters with hybrid drive technology are to be developed and evaluated. The overriding motivation is to increase sustainability and reduce production costs as essential contributions to environmentally friendly aviation.

Objectives

The "ELECTRON" sub-project aims to optimise composite technologies under economic and ecological aspects for a specific application - a complex shell component of the airframe of a helicopter with a hybrid-electric drive system. In this context, fire protection plays an important role due to the battery systems to be carried along. Research into new types of ceramic systems offers the potential to create new types of solutions that are potentially capable of meeting stricter requirements due to stricter regulations. The aim of the work package "Innovative fire protection concepts with ceramic matrix systems" at HTL is to develop a new type of composite material including a ductile seal against operating materials for firewall applications in helicopters. The new CMC material is to consist of a ceramic matrix and an inorganic fibre reinforcement. Inexpensive reinforcing fibres (glass, basalt, ceramics) and a matching ceramic matrix are to be used.

ceramic matrix should be used.

- Application temperatures in case of fire > 600 °C

- Sintering temperature of the ceramic matrix < 700 °C

Approach

- Manufacture of simple composite panels of the novel CMC to demonstrate material compatibility and to determine mechanical properties

- Handover of the prototype components to the component recipient Airbus Helicopters for testing under operating conditions

- Final design with regard to component thickness, component shape and material combination in accordance with the specifications of the component recipient Airbus Helicopters

Project Data

| Project Duration | 01.01.2022 - 31.12.2025 |

| Sponsor |

Luftfahrtforschungsprogramm VI |

| Funding Amount | 343,300 Euro |

Project Partners

|

Fraunhofer-Centre HTL Fraunhofer IGCV Airbus Helicopters Deutsches Zentrum für Luft- und Raumfahrt DLR University of Stuttgart

|

Project Coordination

|

Fraunhofer-Institut für Gießerei-, Composite- und |

| Project Management at the HTL | Peter Vierhaus |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth