Sustainable thermal processes are a focus of research and development activities at Fraunhofer Center HTL. This includes issues such as the conversion of thermal processes to CO2-neutral operation, for example through the use of green hydrogen as a heat source, or the general switch from gas-fired heating to electric heating. In addition to these approaches, which usually involve investment costs for the user, the HTL also offers a systematic methodology for optimizing thermal processes that does not require structural changes to existing thermal process systems. In a material-centered approach, the behavior of the material to be heated in the thermal process is first precisely measured (see High Temperature Characterization). With the help of digital process models or digital twin furnaces, the optimal process control is then determined. The efficiency gain is achieved both through minimal process duration and through optimized product quality (minimal scrap rate). Simply by applying the optimized furnace parameters, the cost and CO2 footprint can be reduced by about 10-20%, often even more.

Process Optimization

Methodology

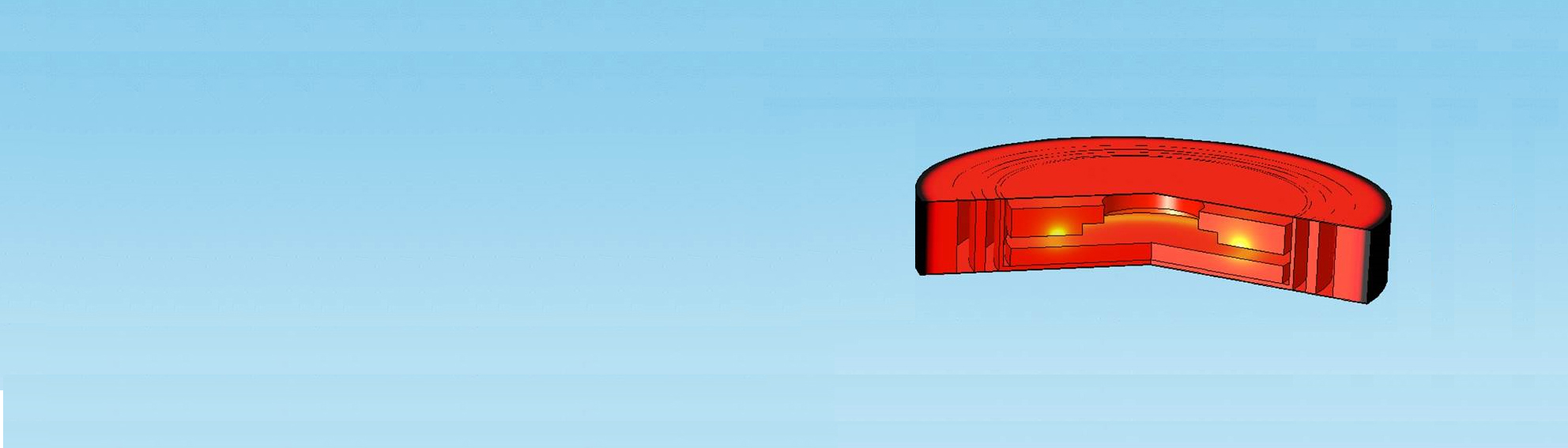

The complete methodology starts with a green body analysis, as defects from the forming process in the thermal process are usually not able to heal. Subsequently, the material-specific changes during the following thermal treatment are characterized by in-situ measurements. Based on the measurement results, the processes for the specific product geometry are simulated on the computer and the optimal process parameters are determined and validated.

Service Offering:

- Support for process optimization throughout the entire production chain using targeted, computer-based methods with regards to:

- Energy efficiency

- CO2 footprint

- Economic viability (reduction of scrap and improvement of product quality)

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth