Completed funded project

Motivation

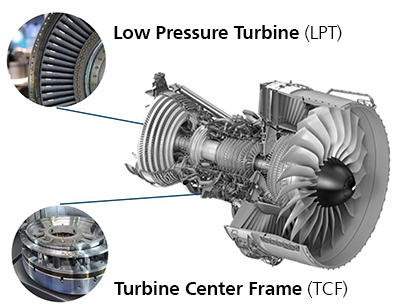

For a more environmentally friendly aviation system, it is necessary to further increase the efficiency of passenger engines. This can be achieved by improving efficiency and reducing the weight of the turbine. At present, metallic superalloys are used, but their technical possibilities are exhausted. Ceramic matrix composites (CMC) not only have a lower weight, but also have the potential to be used at higher temperatures, which leads to higher efficiencies.

Objective

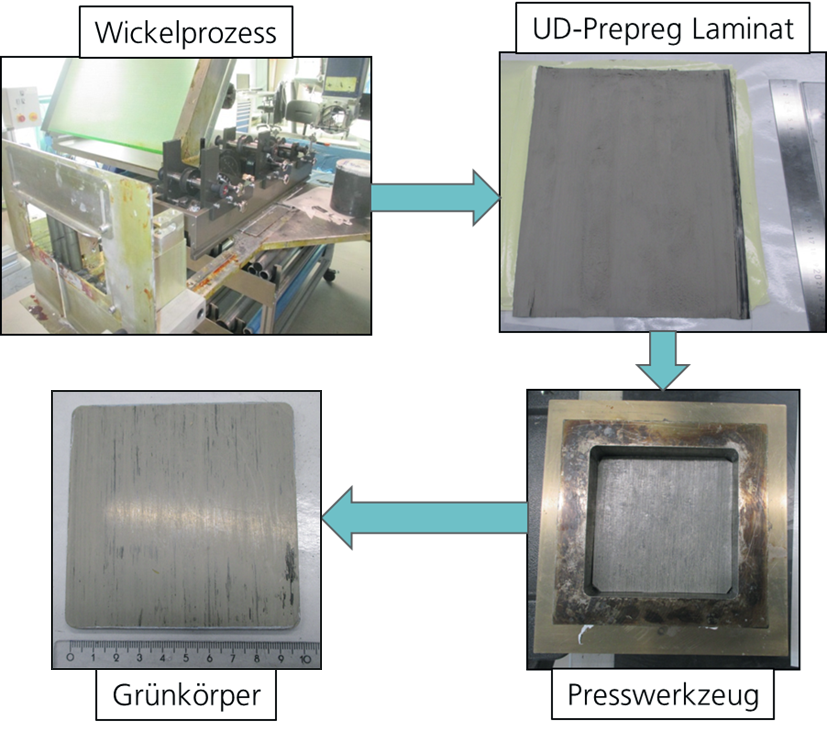

The project aims to develop a silicon carbide (SiC/SiC) material reinforced with silicon carbide fibres to meet the requirements for use in an aircraft gas turbine. This novel material will be used to produce a demonstrator component with all necessary characteristics in terms of strength, component complexity and hot gas resistance. In cooperation with the Fraunhofer alliance ADVANCER, the main focus is on developing a reproducible manufacturing process in a closed process chain with which CMC components can be produced for the end user MTU.

Results

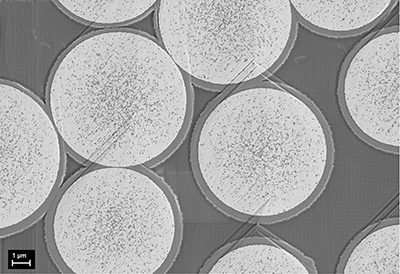

The main results at the HTL include the further development of the Schlicker LSI route - a gentle siliconization process of coated SiC fibers. Drastic savings in development times and costs were achieved by means of mini-composite tests. The use of the ThermoOptic Measuring System TOM_ac, in which, among other things, dynamic immersion silicidation was tested, also showed that low silicidation temperatures, a reduced dwell time and the use of boron-doped silicon (eutectic melt) enable improved LSI processing. A bundle of measures can now better protect coatings and SiC fibers from silicon attack. In the field of wet chemical deposition, crystalline BN coatings have been deposited which, in samples produced by the PIP route, lead to increased damage tolerance and can be produced much more cost-effectively than corresponding CVD coatings.

Project Data

| Project Duration | 01.11.2017 - 31.12.2021 |

| Sponsor | Bundesministerium für Wirtschaft und Energie |

| Funding Amount | 891,300 Euro |

| Project Partners | Fraunhofer-Centre HTL Fraunhofer-Institute for Ceramic Technologies and Systems IKTS Fraunhofer-Institute for Production Systems and Design Technology IPK Fraunhofer-Institute for Mechanics of Materials IWM German Aerospace Centre FAG AG MTU Aero Engines AG Schunk GmbH & Co. KG |

| Project Coordination | MTU Aero Engines AG |

| Project Management at the HTL |

Dr. Alexander Konschak |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth