Completed funded project

Motivation

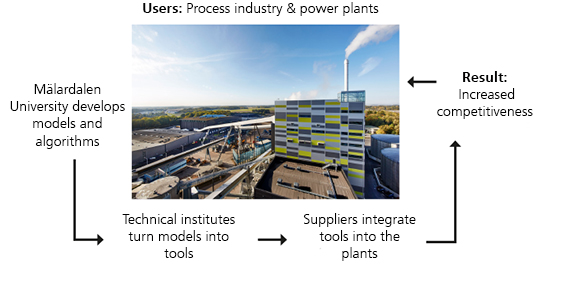

The European process industry faces the challenge of continuously improving its resource and energy efficiency in order to remain economically successful and help achieve the EU's climate and environmental objectives. A promising approach to this is the automated, plant-wide control of resource-intensive processes with algorithms that use machine learning. Key to the success of this concept are, on the one hand, the measuring methods and sensors for recording the required information and, on the other hand, physical models that enable process control during regular plant operation.

Objective

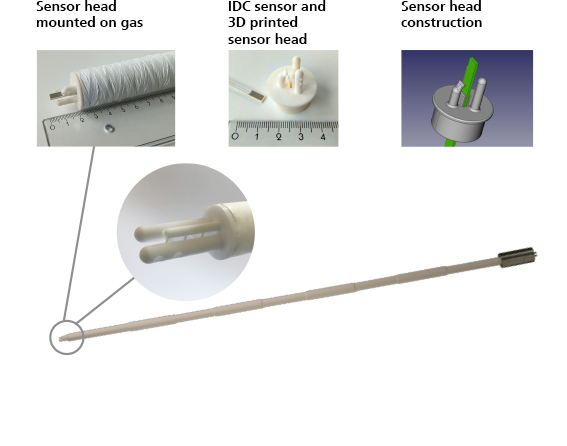

2 m long measuring lance made of O-CMC for measuring high temperatures, gas volume flows and gas compositions

- Overall objectives of the project consortium:

- Development of a software toolbox for monitoring and optimised process control in different industrial plants

- Further development and testing of sensor systems (TOM, FOM, RF, NIR)

- Tests in industrial plants of the project partners / Demonstration of the potential for other sectors, e.g. for the ceramics industry

- Development of a software toolbox for monitoring and optimised process control in different industrial plants

- Subgoals of the Fraunhofer-Centre HTL

- Development of methods for detection and modelling of hot gas corrosion processes

- Development of in-situ control methods for ceramic production

- Integration of the sensor systems in FuDiPO-Toolbox

- Development of methods for detection and modelling of hot gas corrosion processes

Results

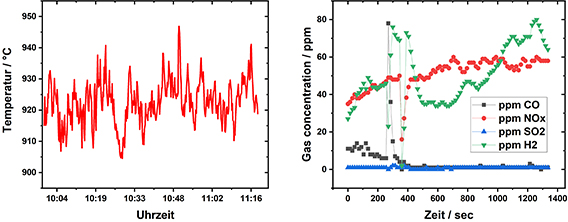

Test of the measuring lance with the sensors in the waste-fired power plant at the project partner MälarEnergi in Västerås / Sweden

Measurement examples for temporal fluctuation of temperature and gas components in the hot boiler zone

- Simulations on the sensitivity of interdigital condensers (IDC) to ash / dust in incinerators and experimental validation

- Development of special 3D-printed ceramic measuring heads for OCMC gas measuring lance with the measuring functions temperature, gas composition, humidity, precipitation (ash)

- Functional tests of IDC sensors and measuring lance

- in laboratory furnaces at HTL (roller furnace, TOM_Chem)

- in waste incineration plant in Västerås (Sweden) at project partner MälarEnergi

- Further development of autonomous high-temperature sensor box for in-situ data acquisition in ceramic production furnaces

Project Data

| Project Duration | 01.10.2016 - 31.01.2021 |

| Sponsor | EUROPEAN COMMISSION Horizon 2020 - Research and Innovation Framework Programme |

| Funding Amount | 433,500 Euro |

| Project Partners | Fraunhofer-Centre HTL Mälardalen University Bestwood AB Optimización orientada a la sostenibilidad SL ABB AB Billerudkornas aktiebolag Mälarenergi AB Turkiye Petrol Rafinerileri Anonim Sirketi TIETO AUSTRIA GMBH Micro Turbine Technology BV |

| Project Coordination | Mälardalen University, Västeras, Schweden |

| Project Management at the HTL |

Dr. Gerhard Seifert |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth