Completed funded project

Motivation

Silicon carbide fibre-reinforced silicon carbide (SiC/SiC) has a wide range of applications for high-temperature use up to 1500 °C. The material is to be used for aircraft gas turbine components. Further applications are expected in the short term for furnace components and in the longer term also for stationary gas turbines and light water reactors. To achieve market maturity, possible manufacturing routes and material formulations must be investigated and defined.

Objective

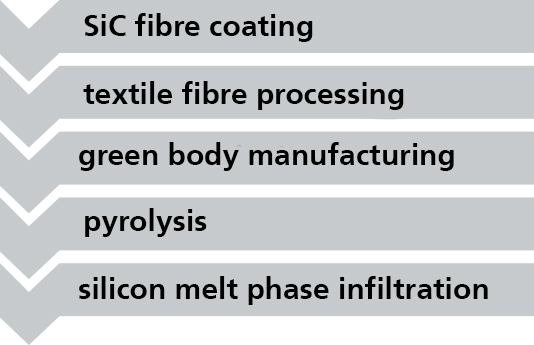

The main objective of the development was a high-strength and damage-tolerant SiC/SiC material, which is produced by the Liquid Silicon Infiltration (LSI) process. The technological basis for the development of material samples was the processability of the highly rigid SiC fibres. By simulating the CMC materials and determining the material properties, the aim was to determine the optimum material structure. The feasibility of a selected process route was to be demonstrated by the reproducible production of CMC demonstrators.

Results

The project was worked on in 7 sub-projects:

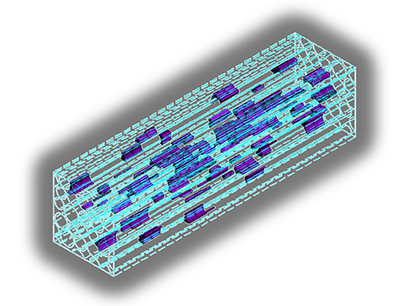

- Sub-project 1: Novel microstructure model for fibre bundles on microstructure level

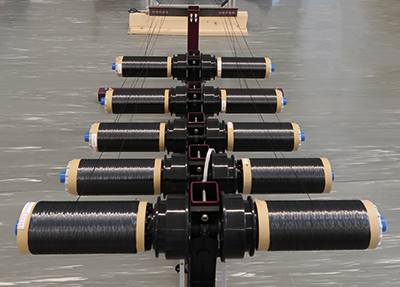

- Sub-project 2: Continuous textile UD-tape production with SiC-fibres for winding bodies and for prepreg technology

- Sub-project 3: Continuous and by order of magnitude more cost-effective wet chemical process - incomparision to vapor phase deposition

- Sub-project 4: Special slurry formulations for fibre-friendly LSI process

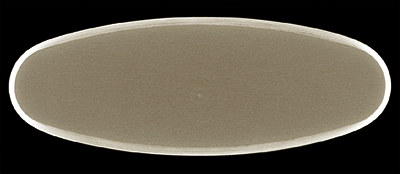

- Sub-project 5: Rapid development loop through the use of "mini composites"

- Sub-project 6: First application of the TOM methodology for the characterisation of CMC

- Sub-project 7: Quality assurance of the entire process by recording all process date in a central database

Project Data

| Project Duration | 01.10.2016 - 30.09.2019 |

| Sponsor | Bavarian State Ministry of Economic Affairs and Media, Energy and Technology |

| Funding Amount | 2,000,000 Euro |

| Project Coordination |

Fraunhofer-Centre HTL |

| Project Management at the HTL | Dr. Jens Schmidt |

|

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth