Completed funded project

Motivation

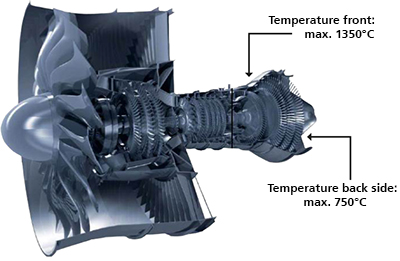

Fibre-reinforced ceramics (Ceramic Matrix Composites, CMC) have the potential to replace nickel-based alloy components in the low-pressure turbine section of an aircraft engine (e.g. outer air seals, casing structures, stators). Due to the significantly lower density of fibre-reinforced ceramics compared to nickel-based materials, a weight reduction of up to 60% can be achieved by substituting metallic components with CMC materials.

Objective

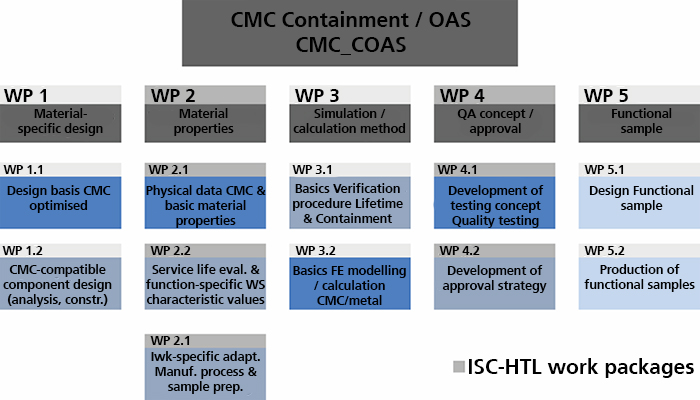

In the project, material characteristics, service life properties and lightweight construction concepts of commercial oxidic and non-oxidic CMC materials were to be determined specifically for the design of engine components. For a future aviation certification of fibre-reinforced ceramics, the basis for a quality assurance concept as well as for a certification strategy was developed.

Results

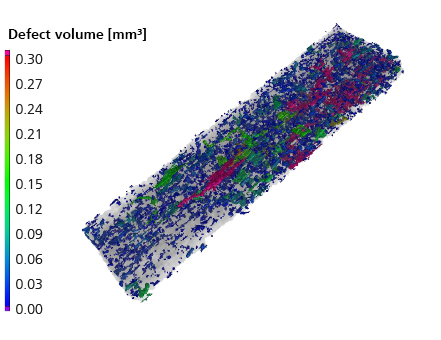

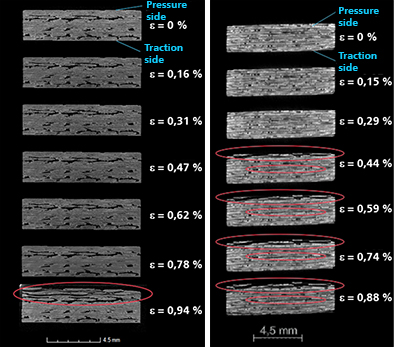

Commercially available ceramic composite materials (CMC) were evaluated in defined fields of properties with a view to subsequent aerospace certification. Both oxide ceramic composites from DLR Cologne and Pritzkow Spezialkeramik as well as silicon carbide fibre-reinforced silicon carbide (SiC/SiC) from MT Aerospace and SGL Carbon were evaluated using destructive and non-destructive testing methods. Similarly, methods for the aerospace-specific testing of CMC as well as concepts for quality testing and quality assurance were developed. Within the scope of the aviation-specific evaluation of commercial CMCs, extensive material characteristics were determined and linked in the form of a database. The determination of characteristic values was concentrated on the following areas:

- Determination of mechanical parameters of CMC materials at room temperature under static and dynamic load (fatigue tests up to 20 million load cycles)

- Determination of thermal and mechanical parameters of CMC materials in the high temperature range up to 1000°

- Investigation of the effects of enginge-specific environmental influences on the material properties

Project Data

| Project Duration | 01.10.2012 - 31.03.2016 |

| Sponsor |

Federal Ministry of Economics and Technology |

| Funding Amount | 500,000 Euro |

| Project Partners | Fraunhofer-Centre HTL MTU Aero Engines AG German Aerospace Centre MT Aerospace AG SGL Carbon SE |

| Project Coordination | MTU Aero Engines AG |

| Project Management at the HTL | Christian Eckardt |

|

|

|

|

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth