Completed funded project

Motivation

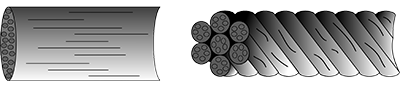

Previous developments for the textile processing of basalt were largely oriented towards rovings. This does not allow the use of all textile-technical processes and areas of application, since basalt rovings are limited in their processability due to their brittleness.

An alternative are staple fibre yarns in which fibres of defined lengths are mechanically spun into a yarn. Staple fibres give the yarn a better bending resistance, which is particularly important at small deflection radii.

Objective

The objectives of the project were the development of novel basalt staple fibre yarns and their further processing into technical textile fabrics. The aim was to combine the advantageous material properties of basalt with the favourable textile processing properties of staple fibre yarns.

Results

Basalt rovings cut to the required lengths were mechanically opened to single fibres and mixed with synthetic fibres. In the following spinning process, the adjustments of machines for fibre protection were of particular interest. This served both the yarn quality and the protection of the plant technology against fibre dust. The second focus was the production of textile fabrics. A small warp beam was made in order to parallelly feed approx. 1500 basaltic staple fibre yarns to the weaving machine. Along with the weft thread inserted crosswise, they formed the fabric base of a pile fabric. The processing properties of basalt fibres are far more complex than those of classic textile fibres due to their brittleness. Nevertheless, the project successfully passed through all processing steps from spinning to weaving and finishing.

Project Data

| Project Duration | 03.07.2017 - 31.12.2019 |

| Sponsor | Bavarian Research Foundation |

| Funding Amount |

133,500 Euro |

| Project Partners | Fraunhofer-Centre HTL / Fraunhofer-Application-Centre for Textile Fibre Ceramics TFK Die Spinnerei Neuhof GmbH & Co. KG E. Schoepf GmbH |

| Project Coordination |

Fraunhofer-Application-Centre for Textile Fibre Ceramics TFK |

| Project Management at the HTL/TFK | Sabine Olbrich |

|

|

|

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth