Completed funded project

Motivation

Tubular structures made of ceramic matrix composites (CMCs) are used in the aerospace industry in particular because of their high torsional stiffness and temperature resistance combined with low weight. The fiber pre-bodies of the structures are currently mostly produced by winding or braiding processes. However, this method has disadvantages with regard to the mechanical properties in the form of delamination, low torsional stiffness or low tensile strength. Furthermore, high costs limit the use of CMCs.

Objective

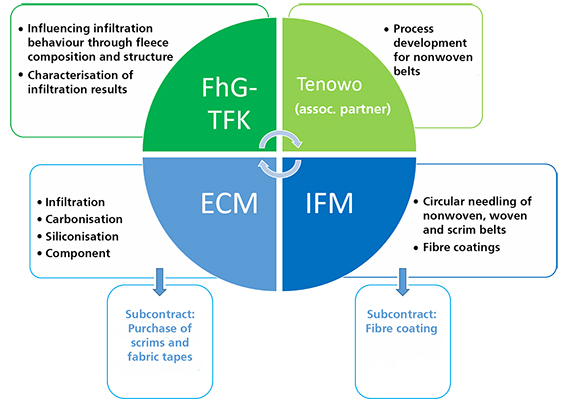

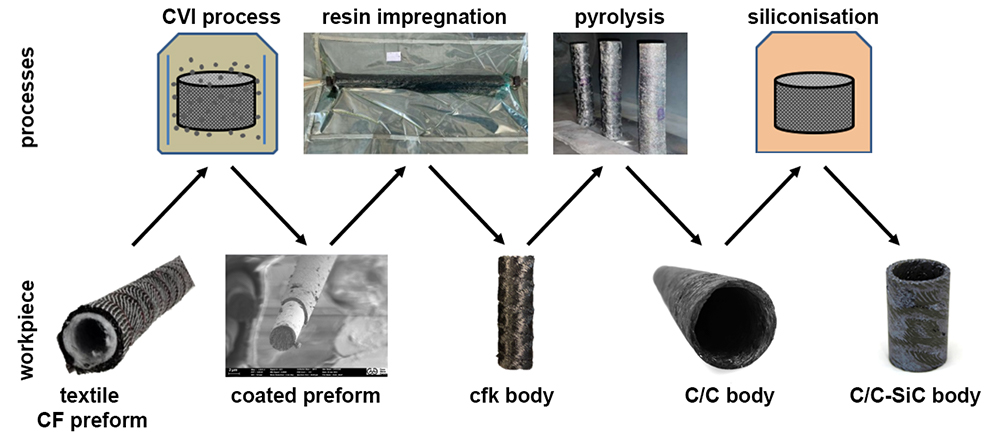

Round needling of textile semi-finished products is to be used to produce tubular structures with increased fiber content in the Z-direction. Thereby improved properties in form of an increased interlaminar shear strength shall be achieved. Shorter production times in comparison to winding or braiding techniques will also enable a reduction in manufacturing costs. The infiltration, carbonisation and siliconisation processes are carried out by the project partner ECM. The Institute for Materials Science (IFM) in Münchberg is responsible for the development of the needling technology and the construction of the structures, while Tenowo GmbH is responsible for the nonwoven production process to realise a functionalised mixed-fiber nonwoven. At Fraunhofer Center HTL, the nonwoven structure for optimum infiltration behaviour is defined.

Results

- Successful production of textile semi-finished products from carbon fibers by means of circular needling to near-net-shape preforms

- Thermal expansion of 3.5-4.0 x 10-6K-1 in the temperature range from room temperature to 1100°C

- Agreement of the measured values at room temperature up to 500°C with the values calculated in the simulation

- Thermal conductivity of 18-26 W/mK achieved, further optimization would be possible by reducing the proportion of pores within the pipe structures

- Fiber volume content of 35% in the target range (< 50%)

- Target outer diameter of 40-45 mm achieved after finishing the C/C-SiC tube structures

- Target tensile strength of 200 MPa not yet achieved, potential for standard methods for determining the strength of tubular ceramic composites

- A method for tube tensile testing was developed as part of the project, still requires the evaluation of elongation

Project Data

| Project Duration | 01.04.2020 - 30.6.2023 |

| Sponsor |

AiF - German Federation of Industrial Research Associations |

| Funding Amount | 285,000 Euro |

Project Partners

|

Fraunhofer-Center HTL ECM - Engineered Ceramic Materials GmbH IFM - Institute for Material Sciences at Hof University of Applied Sciences Tenowo GmbH |

| Project Coordination | ECM - Engineered Ceramic Materials GmbH |

| Project Management at the HTL | Felix Meier |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth