Completed funded project

Motivation

The overall objective of the project is the additive production of fibre-reinforced SiC/SiC and C/SiC components with significant property and environmental advantages over conventionally processed ceramics. The first step is the development of fibre-filled granulates for the additive production of short fibre reinforced preforms, which are further processed by reactive infiltration with molten silicon to form complex Ceramic Matrix Composites (CMC) structures. Short fibre or particle-reinforced CMC with isotropic properties are particularly suitable for the manufacture of geometrically complex but compact components which are subjected to high loads in different load combinations and load directions and additionally to very high temperatures. Examples are fittings of all kinds as well as nozzles, combustion chambers, turbine parts, brake discs, high-temperature fans or structural parts for optics.

Objective

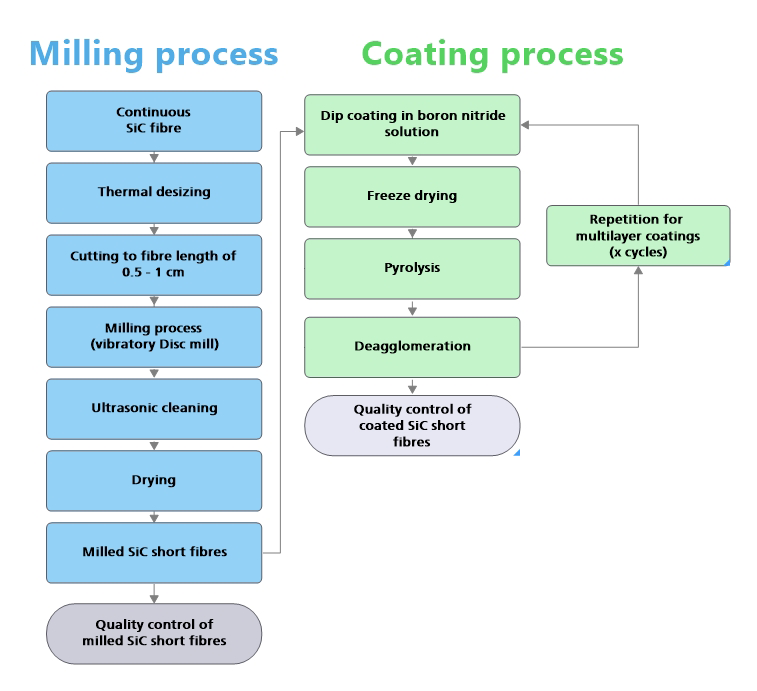

Within the scope of the individual project of the Fraunhofer-Center HTL, a coating of ceramic short fibres using a fluidised coating process is to be developed. Ideally, the short fibres should be completely covered with a boron nitride coating so that the end faces are also coated. The coating is intended to adjust the bonding of the fibres to the matrix in such a way that an improvement of the mechanical characteristics of the additive produced short fibre reinforced CMC is achieved. The coated short fibres are processed by the project partners into CMC by means of additive manufacturing processes.

Results

- Milling process for the production of SiC short fibres with defined average lengths successfully developed

- Scalable, cost-effective dip coating process successfully developed

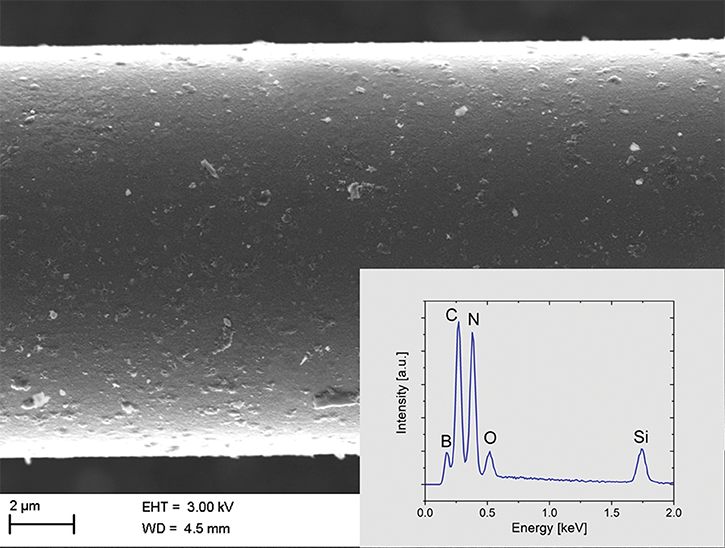

- Complete cladding of SiC short fibres with boron nitride coating

- Boron nitride coatings are crystalline with desired hexagonal modification

- Boron nitride coatings without oxygen impurities

→ improved thermal stability of the coatings

Project Data

| Project Duration | 01.04.2019 - 31.12.2022 |

| Sponsor | Bavarian State Ministry of Economic Affairs, Regional Development and Energy |

| Funding Amount | 50.000 Euro |

| Project Partners | Fraunhofer-Center HTL Ariane Group GmbH Kyocera FineCeramics GmbH |

| Project Coordination | Ariane Group GmbH |

| Project Management at the HTL | Dr. Andreas Nöth |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth