Completed funded project

Motivation

The thermal treatment of bulk materials is often carried out on a very large scale, e.g. for clinker firing or the processing of fine iron ore. This requires a correspondingly large amount of energy. In the future, more efficient kiln systems will be needed to significantly improve the CO2 balance. When designing kiln systems for bulk material treatment, there is a lack of reliable material data for the material to be heated during processing. The simulation models for heat transfer in industrial furnaces also require experimental validation so that reliable forecasts can be made for plant planning

Objective

The aim of this sub-project was to develop new measurement methods that can be used to determine the thermal properties of bulk materials during thermal treatment. These methods should also be applicable for the technically particularly important coarse-grained bulk materials. In addition, methods were to be developed to enable the experimental validation of simulation calculations for heat transfer by conduction, convection and radiation.

Results

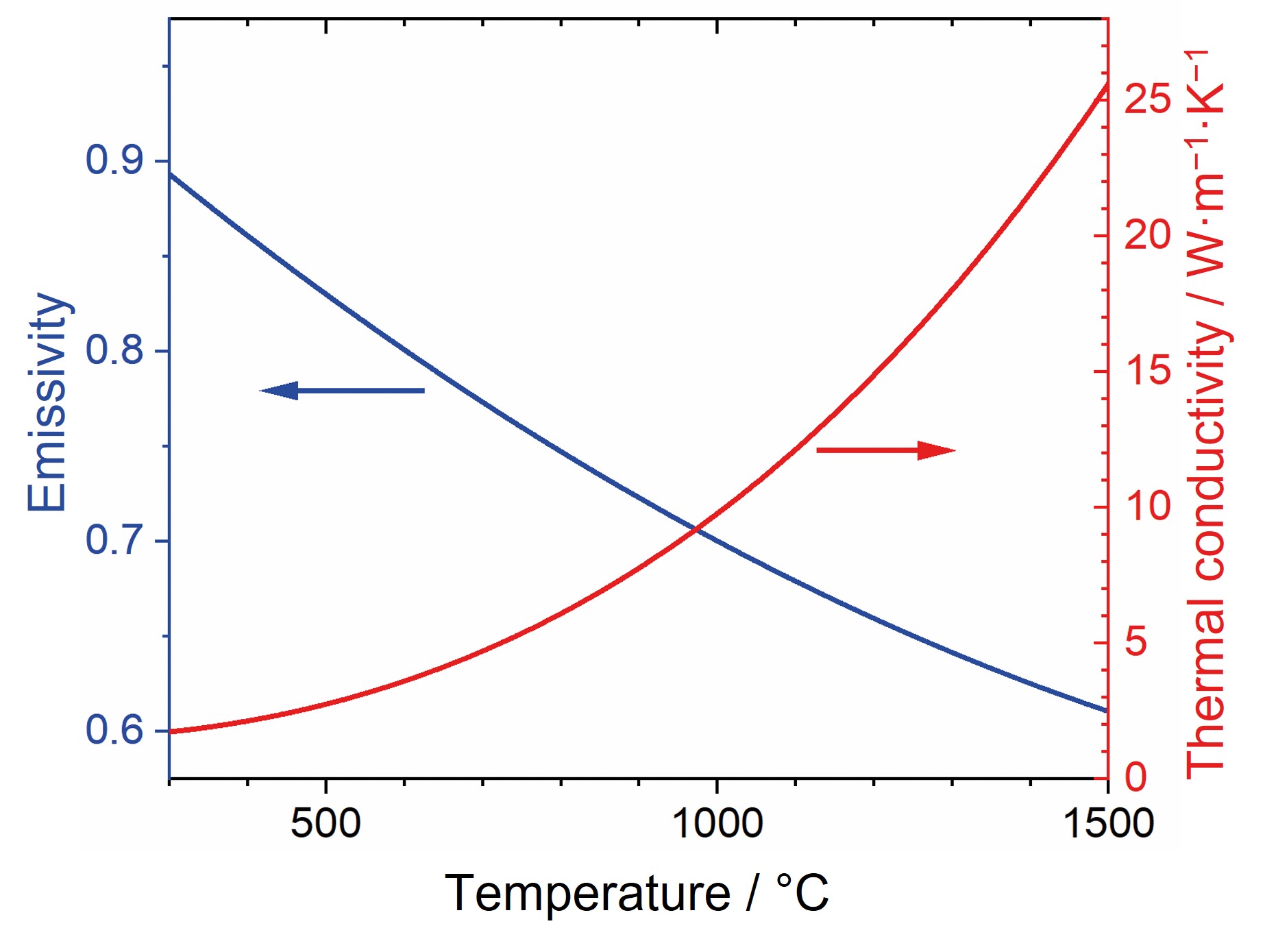

- Measurement of fine iron ore in a crucible up to 1400°C for FE design of thermal treatments on bulk materials: Heat transport in the bulk material is dominated by thermal radiation between particles and increases with the third power of the temperature

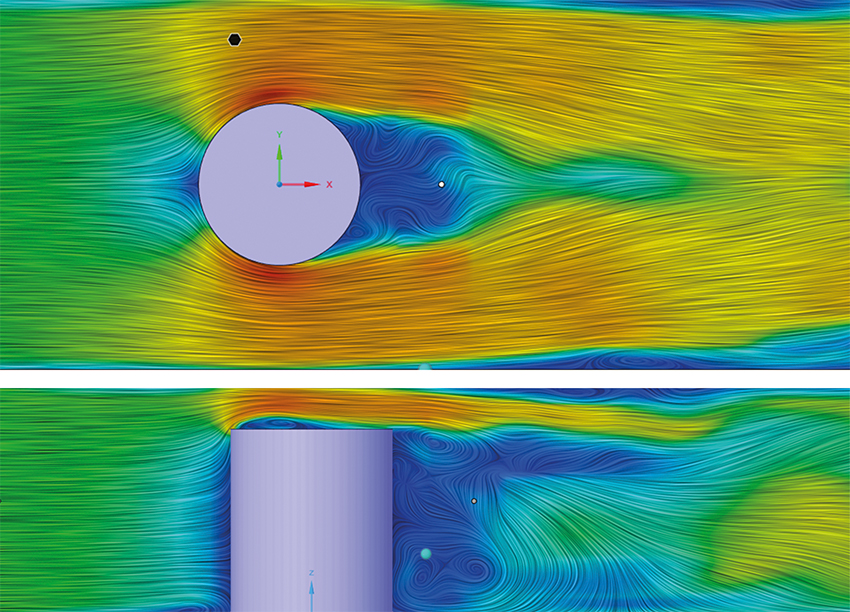

- Determination of the heat flow by radiation at 1200°C via temperature difference measurement in flow obstacles with different levels of occupancy in a radiation channel

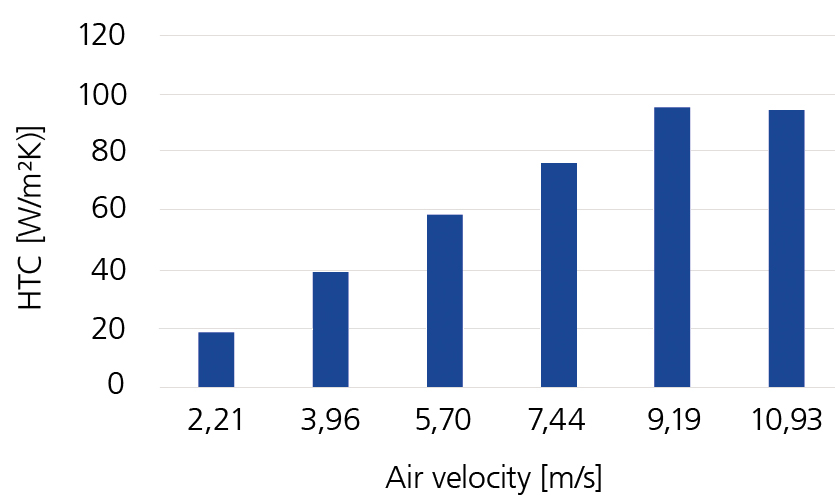

- Measurement of the heat transfer coefficients via a heated flow obstacle in a flow channel

- Measurement of heat flow through furnace insulation by replacing existing furnace insulation in an instrumented furnace door with insulation material to be tested

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth