Completed funded project

Motivation

Thermoprocessing systems are subject to considerable stress due to the strongly fluctuating temperatures. Thermal and mechanical stresses as well as corrosion processes can cause cracks and breakouts in the furnace insulation. The furnace lining must therefore be replaced regularly. If major faults in the lining are not detected and rectified in time, consequential damage and impairment of the product quality of the material to be heated will occur. In a worst-case scenario, accidents in thermal processing systems can lead to serious damage and endanger human life if, for example, hot molten metal is released.

Objective

The aim of this sub-project was to permanently monitor the condition of the furnace lining. The sensor network to be developed for this purpose must be robust and cost-effective and monitor large areas of several square meters, while also reliably detecting very small expansions in the furnace insulation. In addition to the expansion, the temperature should also be recorded locally and the influence of the temperature on the measurement compensated for. Installation must also be simple enough to be carried out by unskilled workers.

Results

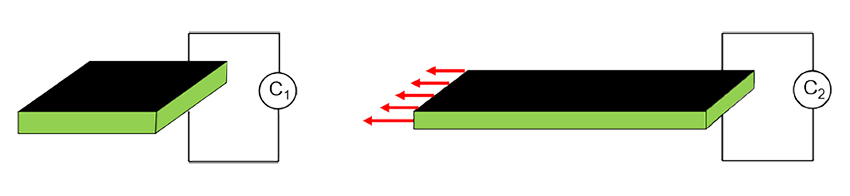

- Capacitive strain sensor with particularly high measuring sensitivity

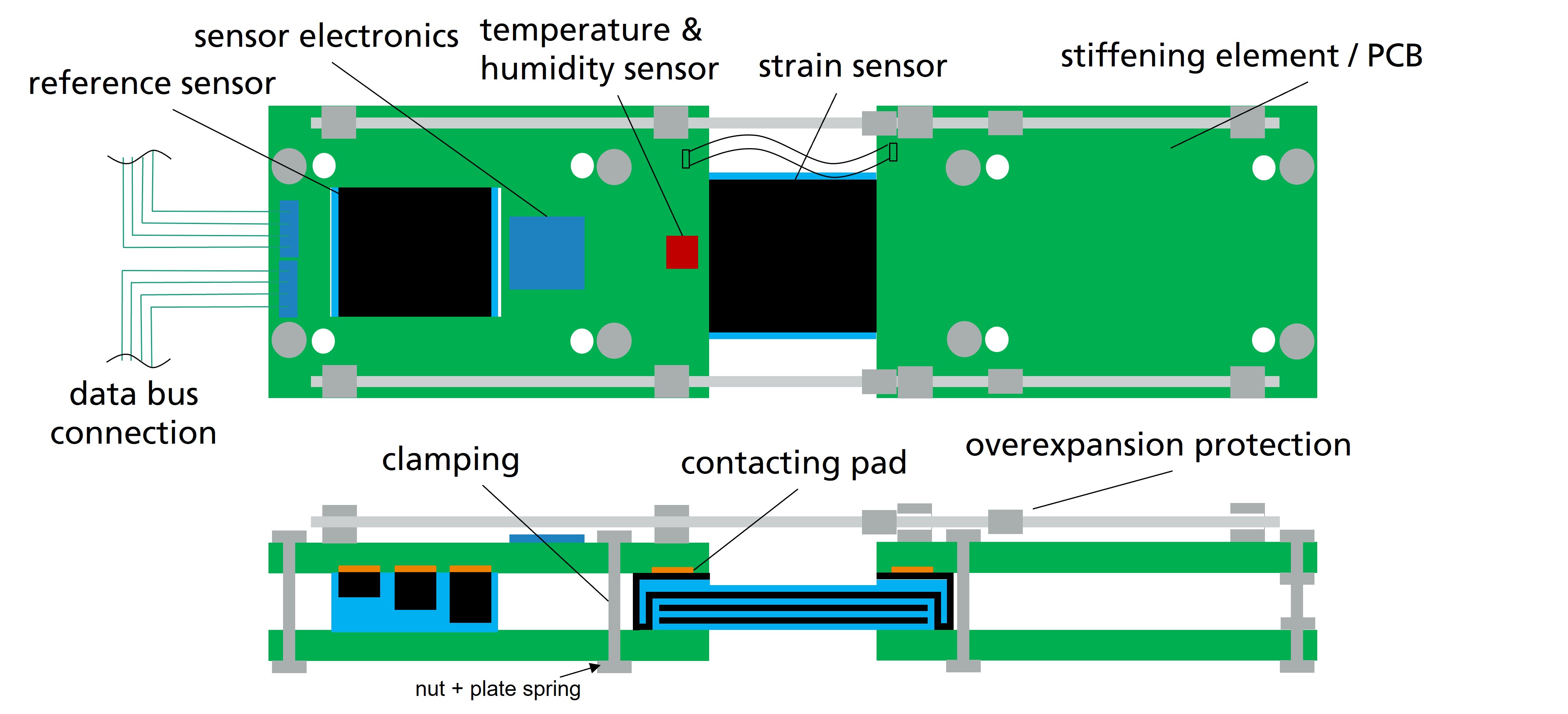

- Modular sensor module with additional reference and temperature sensor for environmental compensation

- Electronic hardware and software for controlling the sensor network and for data evaluation

- Optimization of strain sensor properties with AI methods

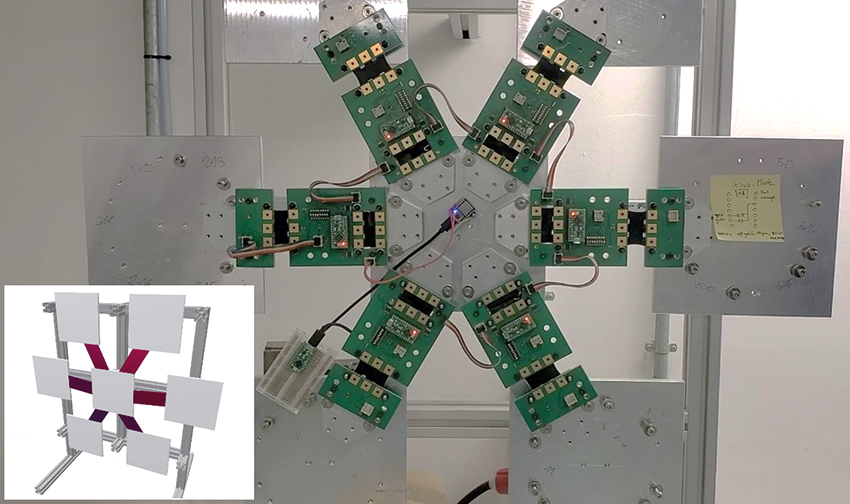

- Setup and demonstration of a two-dimensional strain sensor network

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth