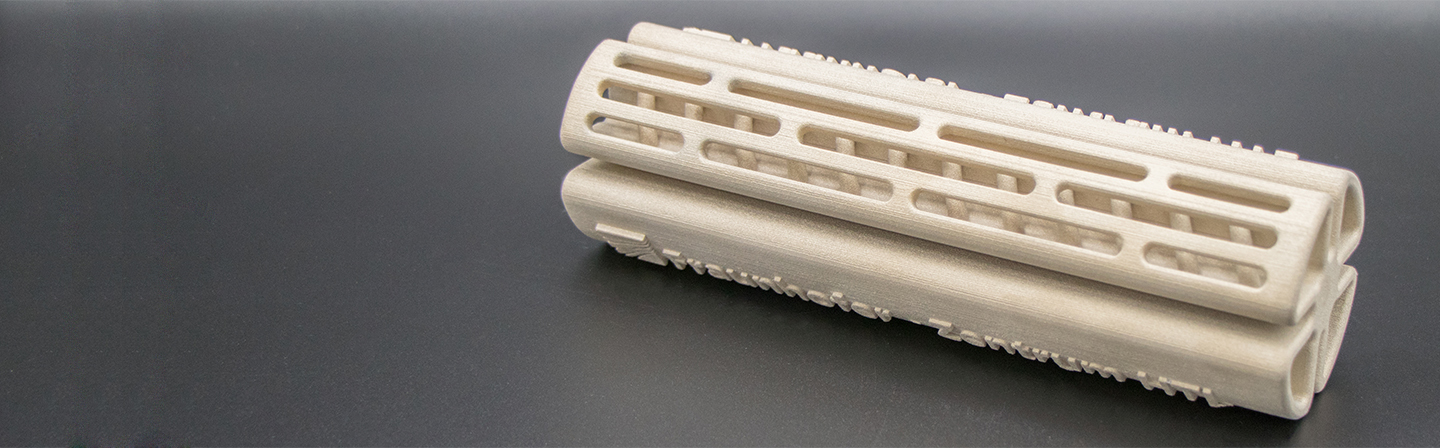

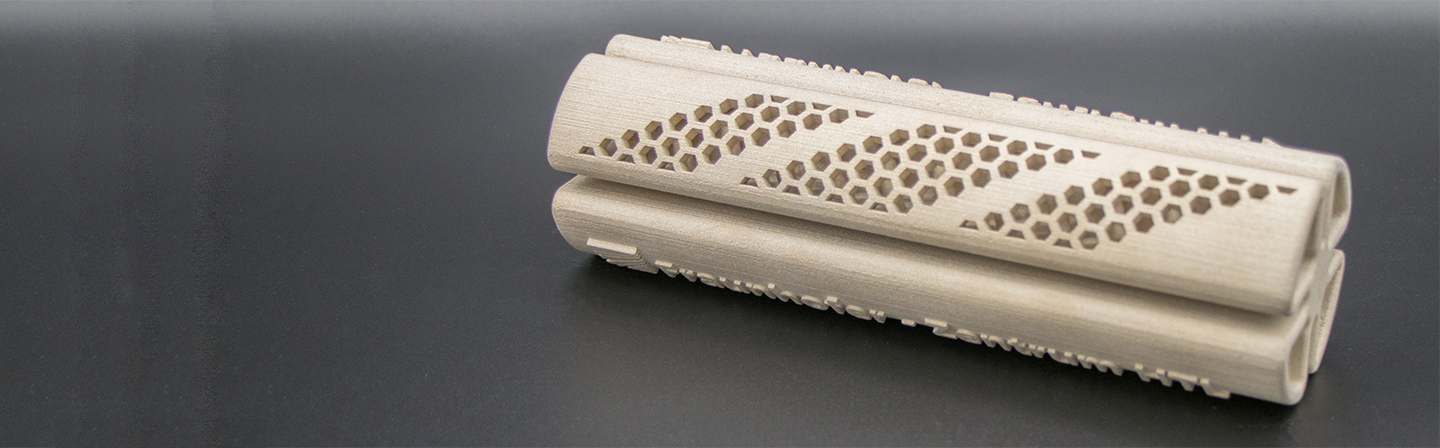

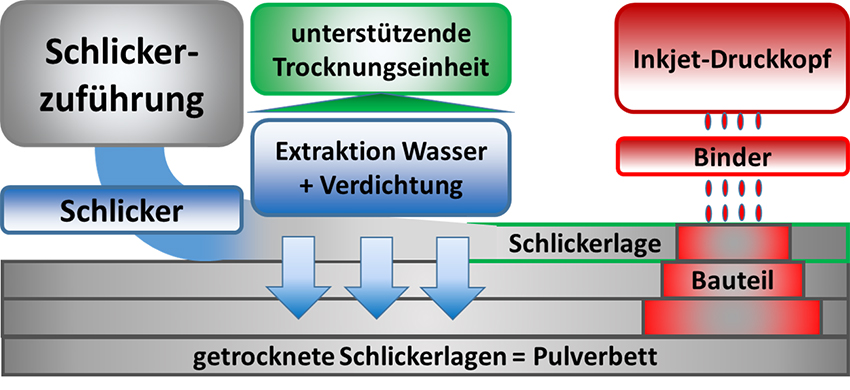

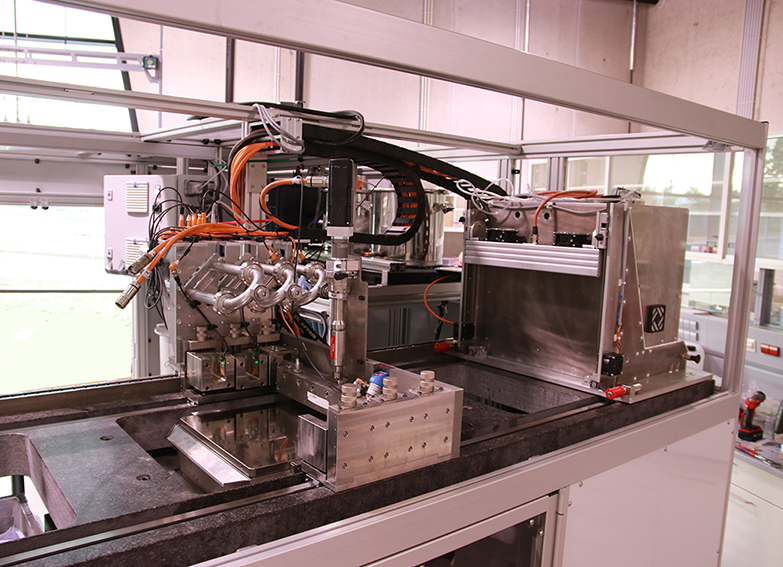

At Fraunhofer Center HTL, new methods for additive manufacturing are being developed and existing ones are being improved. The goal of these developments is to expand the state of the art and subsequently qualify the processes for industrial component production. Future development needs for new additive manufacturing processes are derived from market and customer requirements. Concepts for process implementation are then developed and coordinated with the customer. Subsequently, prototype systems for additive manufacturing can be built according to customer needs.

Requirements for new additive manufacturing processes include, among other things, high green densities, in-situ process control during printing, scalability and cost-effectiveness of the processes, and the ability for 3D multi-material printing. At the same time, the processes must be economically feasible.

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth