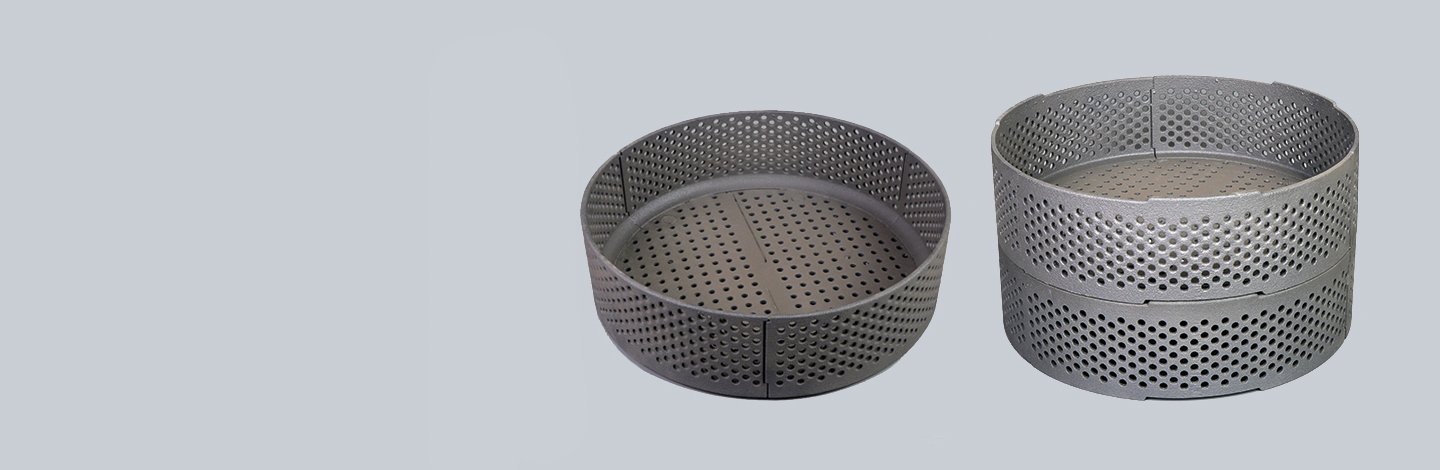

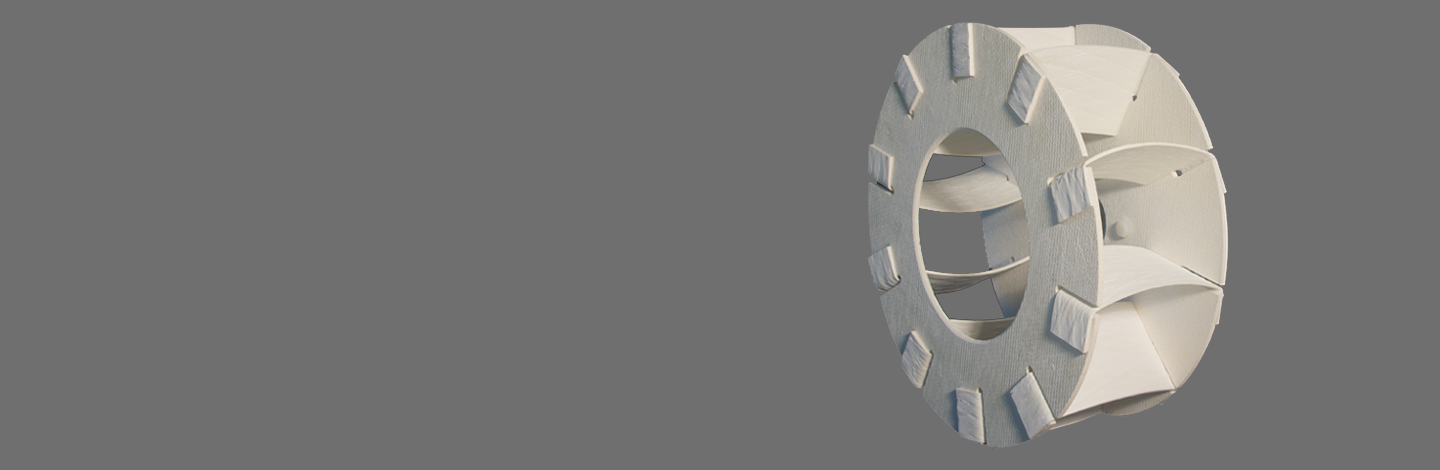

Fraunhofer Center HTL develops components as demonstrators, testable prototypes, or carries out the manufacturing process for small series in closed process chains. Components developed at the HTL are made of ceramic or metallic materials in monolithic form as well as composite materials or material composites. Material composites can be produced by material- and form-fitting connections. Typical component developments at the HTL relate to CMCs, fiber structures, and 3D printed parts including possible combinations, coatings, joinings, and finishing processes.

Prototyping

The specification for prototypes is created jointly with the customer and contains a precise description of the requirements regarding the intended use and system requirements such as temperature, service life, thermo-mechanical stress, and stress from corrosive media. The availability of raw materials or purchased parts, preferred manufacturing techniques, and cost framework are taken into account.

Unless already specified by the customer, the component geometry and the materials to be used are identified by the HTL. A database with several thousand records of commercially available materials is available for material selection. In this database, materials can be searched for based on various criteria (e.g. operating temperature, coefficient of thermal expansion, price, etc.). The component geometry is usually determined by finite element (FE) simulation. The suitable geometry for model components is determined by FE methods in such a way that the test conditions generate similar loads as those expected during use of the actual component.

For the production of components, a production plan for the preferred manufacturing process is usually created based on CAD data. Alternative manufacturing processes are examined to determine the optimal manufacturing process. The HTL offers numerous shaping processes and thermal treatment steps to achieve complex geometries with high component quality. Powder metallurgical processes and processes for the production of CMC are the focus, with prototypes of complex geometries also being produced through additive manufacturing at the HTL. Thermal treatment steps usually follow shaping, which can be optimized using systematic methods and realized with the available furnace technology. Ceramic coatings can be used to protect the surfaces of components against environmental influences such as oxidation or corrosion. Surfaces can be functionalized, or sealed gas-tightly. The HTL offers a wide range of ceramic coating systems for this purpose.

Quality control of components can be carried out at the HTL using non-destructive testing methods. This involves detecting possible defects such as pores, cracks, delaminations, etc. CT can also be used for dimensional control of complex or internal structures. The evaluation of component defects found can be carried out by exporting CT data and subsequent FE analysis of stress concentrations. Further tests and evaluation of components under operating conditions, e.g. at high temperatures, are possible at the HTL (see ThermoOptical Measurement methods).

The HTL also produces small series on behalf of customers if the properties of the prototype components meet customer requirements. The entire production process or individual steps can be delivered to the customer as part of a technology transfer. Patents or licenses from the HTL can also be helpful as part of such know-how transfer, securing market access with the products.

Service Offering:

- Feasibility studies for prototype production

- Research on possible manufacturing processes

- Material selection and component design

- Production of prototypes and small series

- Optional gas-tight sealing and coating of components

- Quality control of components using non-destructive testing methods

- Technology and know-how transfer for materials, products, and processes

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth