At Fraunhofer Center HTL, non-destructive testing methods can be used to examine components and material samples from almost all types of materials, including ceramics, plastics, metals, and composite materials. There is extensive experience in testing and evaluating series components for industrial customers. In addition to non-destructive testing, detailed microstructure examinations can be performed on materials in different manufacturing stages, for example, by preparing sections and examining them using scanning electron microscopy and light microscopy. If necessary, non-destructive testing methods or data evaluation algorithms can be customized to meet specific customer requirements (see Testing Methods). Non-destructive testing methods can also be combined with strength testing to quantify the effects of component defects (see Mechanical Testing).

Non-destructive Testing

Testing Methods

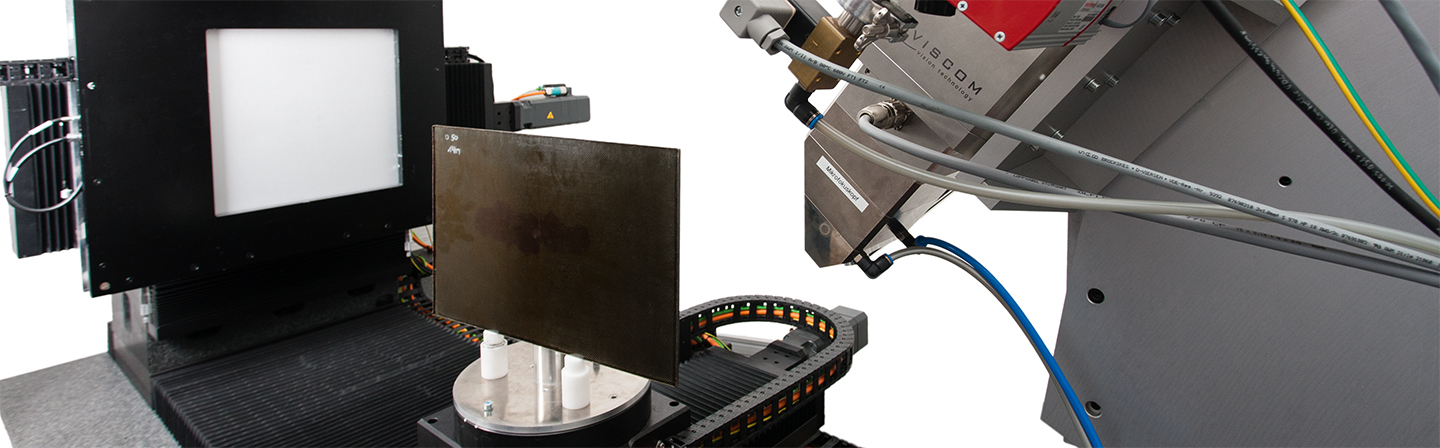

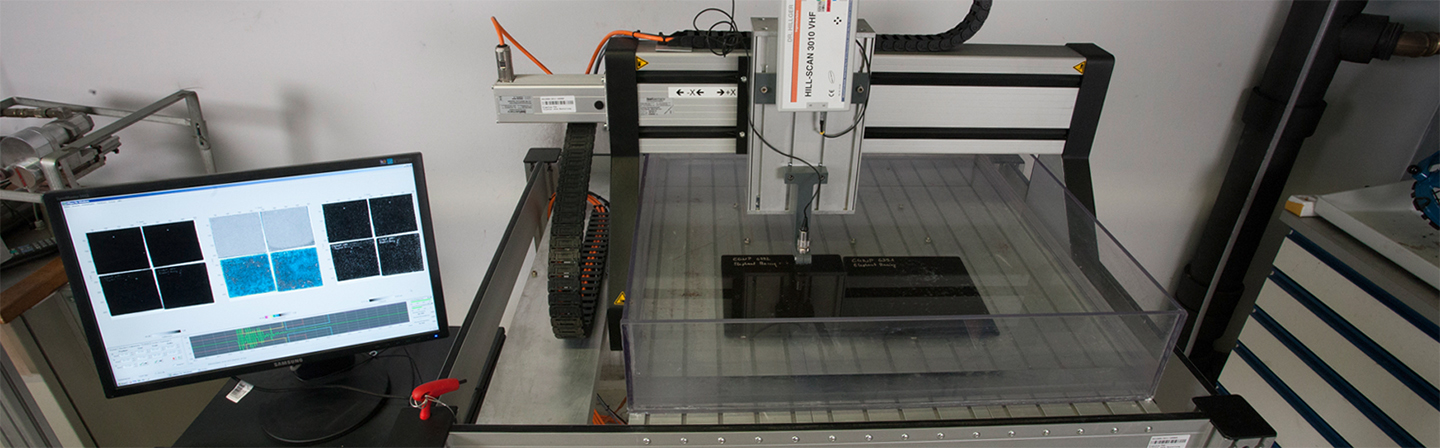

The following testing methods are available for non-destructive testing of components and materials:

- Computed tomography (225 kV and 450 kV radiation sources)

- In-situ setups for mechanical examination during computed tomography

- Water- and air-coupled ultrasound systems

- Thermography (lock-in and thermal imaging)

- Terahertz technology

- X-ray imaging

Service Offering:

- Non-destructive testing of samples and components with dimensions ranging from less than 50 µm to 700 mm in diameter and up to 2000 mm in height

- Dimensional, target-actual, and damage analyses of components

- Volumetric microstructure analysis with 2µm resolution using micro computed tomography

- Failure analysis through comparative computed tomography measurements of components before and after load tests

- In-situ analysis of thermal, mechanical, or chemical stresses using computed tomography and thermography

- Examination of small series and creation of defect catalogs

- Performing microscopic analyses on sections using light microscopy and scanning electron microscopy

- Interpretation of test data in dialogue with customers or project partners

- Creation of test reports

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth