Completed funded project

Motivation

Silicon carbide fibres can be used at higher temperatures than oxide ceramic or glass fibres and have better oxidation resistance than carbon fibres. As a reinforcing component in ceramic composite materials (SiC/SiC-CMC) they are of great importance. The production of high-temperature stable SiC fibres is still based exclusively on the synthesis of expensive polycarbosilanes. The high fibre costs prevent a broad application. Furthermore, SiC fibres are only produced by a few companies in Japan or the USA, and access to the fibres by European companies is very limited.

Objective

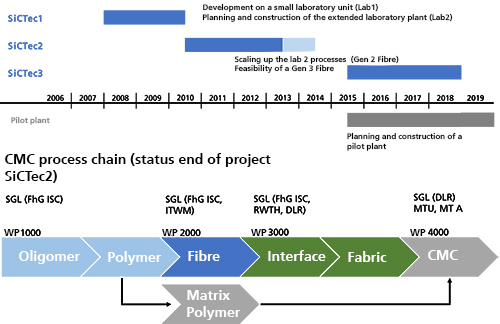

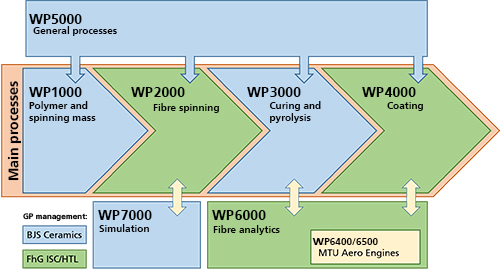

In a joint project between the companies BJS Ceramics, MTU Aero Engines and the Fraunhofer Centre HTL, a high-quality SiC fibre was to be developed to enable European fibre production. The fibre used a polysilane-polycarbosilane as the starting material, which had the potential to reduce costs. The project aimed at scaling up all production steps to a maturity level of at least TRL 4. It should also demonstrate on laboratory scale that SiC fibres can be converted from Generation 2 fibres to Generation 3 fibres by chemical and thermal processes.

Results

- New polymer synthesis route without nitrogen input; pure polysilane (TRL 3-4)

- Production of reproducible spinning masses on a kg scale (TRL 4)

- Reproducible spinning fo polymer solutions into endless green fibre bundles > 200 m length (TRL 4)

- Optimisation of the pyrolysis of green fibres to ceramic fibres with stoichiometric Si:C ratio (TRL 4)

- Coating of the fibres for corrosion protection and matrix bonding (TRL 4)

- Further processing of the coated SiC fibres to CMCs with CVI matrix test of the SiC/SiC-CMC

Project Data

| Project Duration | 01.07.2015 - 31.03.2019 |

| Sponsor | Bavarian State Ministry of Economic Affairs and Media, Energy and Technology |

| Funding Amount | 3,200,000 Euro |

| Project Partners | Fraunhofer-Centre HTL BJS Ceramics GmbH MTU Aero Engines AG |

| Project Coordination | Fraunhofer-Centre HTL |

| Project Management at the HTL |

Arne Rüdinger |

|

|

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth