At Fraunhofer Center HTL, thermal treatment processes for bulk materials are investigated and optimized. On the one hand, measurement methods are being set up with which material properties of bulk materials can be determined as a function of temperature. On the other hand, methods are being developed for optimizing process parameters and for upscaling in production furnaces.

Bulk Material Processes

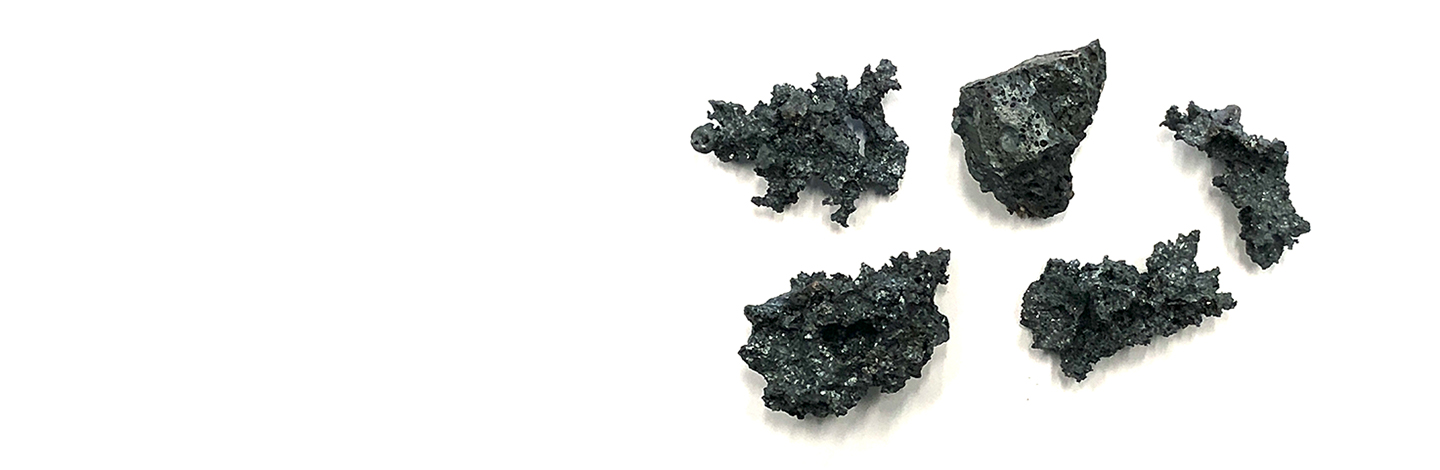

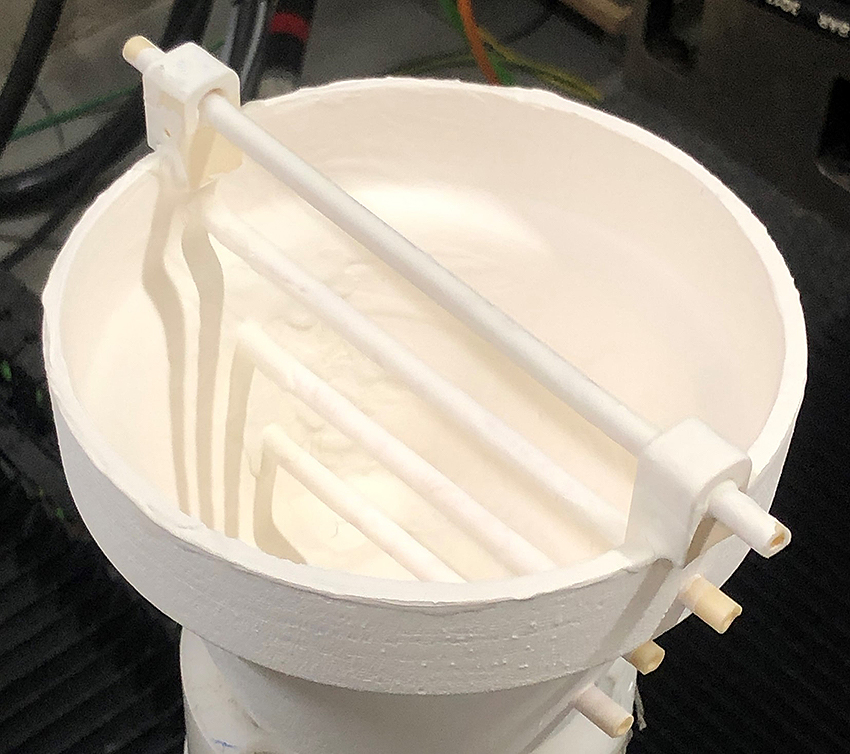

Depending on the grain size, different bulk material quantities are required to obtain representative material data. Fine powders can be analyzed on a milligram scale using the thermoanalytical methods available at the HTL (differential thermal analysis coupled with thermogravimetry and mass spectrometry, as well as differential heat flow calorimetry and laser flash methods). For coarser grains with particle sizes up to 20 mm (medium gravel), crucibles with powder quantities up to the kilogram scale are used. The measuring range of the weight sensors used varies accordingly. Emission gas analyses are carried out with electrochemical sensors for larger sample quantities. Thermal material properties such as thermal conductivity and emissivity are obtained for coarser grain sizes by finite element simulations of heat transport in rotationally symmetrical crucibles and an inverse determination based on comparison with measured temperature distributions (publication: In situ measurement). Dimensional changes are measured in powder piles by shadow casting methods using HTL's thermo-optical measurement methods. Compressive strength is measured as a function of temperature by uniaxial compression tests in appropriate crucibles. Measuring furnaces with different atmospheres are available for the characterization of bulk materials: from pure hydrogen atmospheres to different fuel gas atmospheres to inert atmospheres and vacuum. Drying is investigated in the laboratory in atmospheres with defined humidity and flow velocity. A special drying balance is available for measuring bulk material behavior in industrial drying units.

Optimization of the process parameters of thermal treatments on bulk materials is possible for drying, pyrolysis, redox and sintering processes. The material changes are recorded with in-situ measurement methods and parameterized in form kinetic models. High-temperature measurement data on the respective bulk material are also used for thermal management. The gas permeability is calculated on the basis of room temperature data. Based on these data, process optimization is performed using finite element (FE) simulations of the thermal treatment. FE simulations are also used to scale-up the processes. Customized apps can be created on request to allow users to design their own process optimization. For the design of new types of furnace systems, digital furnace twins can be created at the HTL, enabling an evaluation without having to test all system variants in reality.

Service Offering:

- High temperature measurement of thermal conductivity and emissivity of bulk materials in controlled atmospheres.

- In-situ measurement of other bulk material properties, such as dimensional changes, strength, temperature-dependent mass decrease (thermogravimetry)

- In-situ measurement of gas phase reactions on bulk materials (weight changes, emission gas analysis, calorimetry)

- Optimization of drying, pyrolysis, redox and sintering processes

- Development of customized apps for process optimization of bulk materials

- Development of novel thermal processes for bulk materials using digital furnace twins

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth